ELAT3D Ltd. (Lincoln, UK) has carved out a market niche by 3D printing bones for the medical industry and producing architectural models for architects and surveyors. These are useful items and well adapted to 3D printing technology, but the company was looking to do something a bit more whimsical on the side. "Although we do enjoy making bones and buildings," says the company on its website, it wanted to use the technology to produce something fun and affordable for the larger consumer market.

January 6, 2016

ELAT3D Ltd. (Lincoln, UK) has carved out a market niche by 3D printing bones for the medical industry and producing architectural models for architects and surveyors. These are useful items and well adapted to 3D printing technology, but the company was looking to do something a bit more whimsical on the side. "Although we do enjoy making bones and buildings," says the company on its website, it wanted to use the technology to produce something fun and affordable for the larger consumer market. The answer: Combining facial recognition software and 3D printing to produce replicas of customers' heads that connect to Lego mini figures.

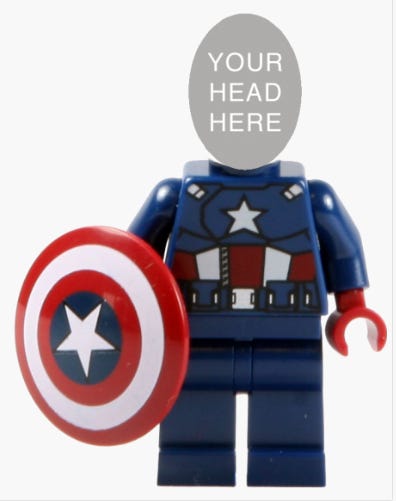

Here's how it works: You send Funky 3D Faces, the subsidiary formed by ELAT3D, front and side photos of your head along with $30.08, and in about two weeks you will receive an "eerily lifelike" 15-mm-high head that fits onto any Lego figurine. You can also purchase minifigs from the company through its Etsy page—an array of superheroes from Captain America to Wonder Woman are available—or you can fit the head onto a figurine you already have.

Creepy, cool or creepy-cool? asks CNET. I vote for creepy-cool.

About the Author(s)

You May Also Like