The trend towards weight saving in the automotive sector is relentless and is becoming increasingly important as the year 2020 approaches—this is when the fleet CO2 emissions of European automobile manufacturers must comply with significantly more stringent requirements.

July 1, 2013

The trend towards weight saving in the automotive sector is relentless and is becoming increasingly important as the year 2020 approaches—this is when the fleet CO2 emissions of European automobile manufacturers must comply with significantly more stringent requirements.

Thermoplastic materials, with both short- and long-fiber reinforcement, have made a major contribution to lightweighting today, because with their help innumerable metal production components were replaced by equally capable plastic counterparts according to resin supplier BASF SE (Ludwigshafen, Germany). Simultaneously, these plastic components and materials are starting to reach their fundamental limits. The next big advance in metal substitution in vehicle construction will succeed only with a technological leap, namely, using continuous-fiber reinforcement of injection molded structures, i.e., with thermoplastic composites, adds BASF.

|

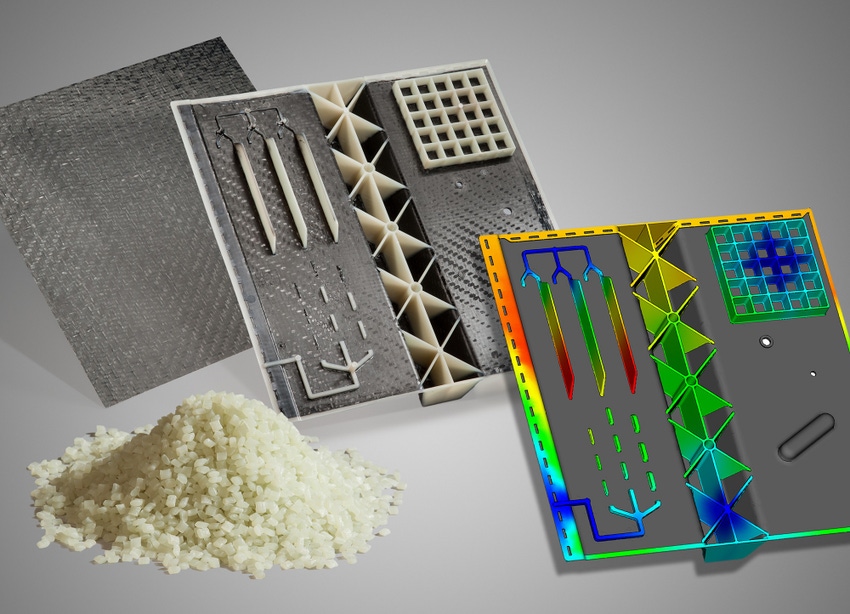

Laminates based on woven fabrics and unidirectional (UD) tapes combined with glass fiber reinforced compounds offer further opportunities for plastics in automotive applications. |

For this reason, BASF is now expanding its activities in the field of engineering plastics to include a completely new approach called Ultracom. This is essentially a package of three components: continuous-fiber reinforced semifinished products; adapted overmolding compounds; and complementary engineering support.

The key innovations in this new approach are laminates based on woven fabrics and unidirectional (UD) tapes that are fully impregnated with Ultramid polyamide (PA) or Ultradur polybutylene terephthalate (PBT) materials from BASF. These thermoplastic composites are being enhanced in a development cooperation together with fiber-reinforced composites manufacturer TenCate and glass fiber supplier Owens Corning.

The second component of the Ultracom package consists of overmolding materials that have been developed specifically for use with these laminates. These materials are also from the Ultramid and Ultradur product lines, this time in the form of compounds. By using them in combination with the laminates and tapes, it is possible to injection mold complex parts that have very high mechanical reinforcement by use of continuous fibers at precisely defined locations while simultaneously incorporating specific functions as the result of overmolding.

At the upcoming K 2013 show in Germany, BASF will already be able to offer its first commercial Ultracom product packages. For projects requiring parts with high stiffness, the package consists of an Ultralaminate based on PA 6 (or an Ultratape if highly directed reinforcements are needed) in combination with Ultramid G12 COM with 60% glass fiber reinforcement as the overmolding compound.

For crash loaded applications with a special need for impact strength, BASF offers a package which is optimized for high energy absorption. This package consists of Ultralaminate and Ultramid ZG7 COM. In this case the Ultratape tape version is available for local reinforcement, for example as required in seat structures. It can be overmolded with the same Ultramid ZG7 COM. For the time being, the orthotropic Twill-2/2 structure commonly employed in technical textiles and PA 6 will be used for the laminates. The first pre-production parts realized by Ultracom will be displayed at the K-Show 2013.

Importance of engineering support

The third component of the Ultracom package is reportedly of great importance for developers of parts made from composites, according to BASF: It covers the extensive engineering support provided by the company' application engineering group.

This includes not only assistance in the form of designing the part on a computer with the aid of the universal simulation instrument Ultrasim, but also support when it comes to processing the material and manufacturing the part. For this purpose, BASF has added a fully automated pilot line combining an injection molding system with automated laminate feeding at its technical center.

The engineering support, is not just an option that can be used when necessary, as it was in previous lightweighting projects: It is an essential component of all customer projects says BASF. Without the ability to optimize design and production and to describe the behavior of the composite materials and the parts numerically via integrative simulation as in the case of the conventional short and long fiber-reinforced thermoplastics, a successful full scale market launch would be difficult to achieve.

In recent years, the Ultrasim simulation tool from BASF has made it possible to develop and design many new parts such as transmission cross beams, engine mounts, engine supports and metal-free front ends. Laminate- or tape-based thermoplastic composite parts will be a viable solution for high-volume production only if integrative simulation is supplemented by new material models and underlying experimental findings according to BASF. The first Ultramidproduction application on the basis of overmolded thermoplastic laminates - at the time manufactured externally - appeared in 2012 in the form of the seat pan for the Opel Astra OPC.

Lower processing costs a key

At present, the greatest technological obstacle is the development and introduction of highly automated and robust process technologies at all partners along the value-added chain, which will also lower the process costs. Currently integrated systems consisting of injection molding machines, molds, automatic positioning equipment and heating structures are not available off the shelf, neither are the individual elements matched to one another. When such equipment become available, thermoplastic composite parts reinforced with continuous fibers will provide the best possible combination of weight savings, cost efficiency and performance for body and chassis components according to BASF.

Laminate or tape?

The two different types of semi-finished products on offer fulfill different functions: while thermoplastic laminates are fiber fabrics impregnated with thermoplastics, unidirectional tapes require layered arrangements that must first be produced from the fully impregnated fiber tapes to create structures. Thermoplastic laminates are thus better suited for quasi-isotropic hybrid parts with a large surface area, while tape-based inserts are more suitable for local reinforcement of injection molded short glass fiber-reinforced parts with anisotropic properties.

Working together with customers in the automotive sector, BASF is giving itself three years to develop production concepts for thermoplastic composites with continuous-fiber reinforcement for body and chassis parts. The company intends to spend a high two-digit-million euro sum on research and development in its composite activities over this period.

You May Also Like