With mold lead times shrinking and customers more demanding on price, many moldmakers are coming up with ways to provide what the customer wants in a fraction of the time. And there are a variety of ways to achieve this, as we see in these three mold companies that have evolved into the “rapid” arena.

April 20, 2009

With mold lead times shrinking and customers more demanding on price, many moldmakers are coming up with ways to provide what the customer wants in a fraction of the time. And there are a variety of ways to achieve this, as we see in these three mold companies that have evolved into the “rapid” arena.

No mold shop today is immune from the “I need it yesterday” syndrome, and customers are becoming increasingly demanding when it comes to lead time. While we’ve heard a lot about rapid tooling using additive manufacturing processes such as direct metal laser sintering (DMLS) from EOS GmbH (Munich, Germany), even conventional mold manufacturers are stepping up the pace to make traditional injection mold building a more cost effective and faster process.

|

Rick Haddock, president and owner of Tool Room Express (TRE; Binghampton, NY), says his company’s approach to rapid tools is more conventional, but with major process modifications. “We don’t use a state-of-the-art approach like SLS or additive processes. Our stock in trade is conventional moldbuilding,” he says, but with some duplication of effort taken out. “Basically, we take the concept of the unit die insert and we have a system designed that gets us closer to the important work of building a mold—cutting the cores and cavities.”

In TRE’s rapid process, all molds are aluminum. In one instance, a customer needed parts within 24 hours, but typically, the company will complete a mold in three weeks or less. It specializes in single-cavity tools, generally used for low-volume projects (5000-10,000 cycles) or functional testing. “They get a true injection molded part made much more quickly and cost effectively, using all the conventional machining methods, including EDM. That’s the benefit to our customers—they don’t have to modify their part to fit our process,” Haddock says.

From traditional to rapid

“We began initially as a traditional tool shop, building the kind of tools nobody else wanted to build,” says Steve Riddle, VP of operations for Advanced Technology (Corona, CA). “We began seeing more demand for shorter lead times, especially in medical startups in the Bay area, where we had a lot of customers. They needed parts so that they could get their products into clinical trials quickly because the goal is to be first into the market.”

Five years ago, Advanced Technology was involved with several companies trying to come up with a new device to detect breast cancer. “Time to market is so critical that it’s this wild race for companies to get there first, and that’s where we’ve seen a lot of our success,” says Riddle, who adds that today the company’s business is about 97% medical.

That’s when the company began changing its philosophy and geared the whole structure toward speed. “We developed our process to cater to that, and since that time it’s been very successful,” says Riddle. “With product life getting shorter ... people are looking to get things quicker and more efficiently with lower capital investments on the tooling.”

Some aspects of Advanced Technology’s process are proprietary, but Riddle shares that it’s multipronged. The key is a metal-based material the company developed that allows them to machine quickly while providing excellent wear characteristics to produce plastic components. “It’s faster than tool steel to machine, but we can warrant the tool life for 2 million parts, which is unheard of with traditional materials,” he says. “Typically, in rapid tooling the customer must sacrifice tolerance or tool life, but we don’t have to.”

Another key to their process, says Riddle, is that the company doesn’t hire conventional toolmakers. “All our people are trained through an in-house apprentice-based system to learn our unique way of building tools, which includes conventional techniques, but eliminates some traditional methods. For instance, we don’t use EDM or some of the slower aspects of conventional toolbuilding.”

Advanced Technology has been in rapid tooling for about 15 years, and Riddle says it’s been an evolution as the company has refined its process. “We advertise that we build tools in 10 working days, but have done it in as little as three to five days,” he says. “We’re always trying to push the envelope and do it even faster. That’s the goal—three to five days.”

From prototyping to traditional, but fast

RapidMolds, a division of the Rapid Tooling Group, a wholly owned subsidiary of Ideas Inc. in Uniontown, OH, builds conventional steel molds in extremely fast lead times. Brad Borne, RapidMolds president, says that the company evolved into conventional mold manufacturing from its beginning as a prototype shop.

“We started in prototype tooling in 1996, and invested in high-speed machining, focusing on aluminum molds using a complete 3D design approach, built with full 3D machining,” Borne explains. “But we soon discovered there’s a limitation to the high-speed machining of aluminum: If you machine it fast enough, it liquefies.”

Borne says the company looked at a variety of processes over the years, but was “turned off by additive manufacturing and decided we weren’t going down that path.” He describes additive manufacturing as making an approximation of an approximation of an approximation. “Building steel tools, we’re not approximating anything, but making an actual production tool.”

In 1999 RapidMolds moved beyond prototype tooling into production tooling in steel, primarily using P-20, H-13, and S-7 hardened steel, and continued to use high-speed machining to meet customers’ demands for short lead times.

“We can cut steel two to three times faster than aluminum because it doesn’t turn into liquid during the high-speed process,” Borne says. “We can make a P-20 tool in the same time or quicker than an aluminum tool because we don’t run up against the limitations, and the cost is basically the same.” RapidMolds can make an SPI Class 104 or “bridge tool” in one to four weeks, and the company guarantees it for 250,000 cycles. Borne says the company “routinely makes hardened steel molds in stand-alone mold bases, even with hot manifolds, in four weeks or less.”

Borne notes that the company has built steel molds in as little as 21 hours. “It can be done, but this is a special option that we do in rare instances. A customer will call and need something in one to three days; we’ll do whatever we can to help them. Last summer, we built a four-cavity mold in five days, and we routinely build similar molds in two weeks,” he says.

The payback for RapidMolds’ customers is they get a production mold in prototype lead times. They’ll pay more at the front end because it’s a steel mold, but Borne explains that in the long run, they benefit from only having to purchase one mold.

For example, a four-cavity P-20 mold from RapidMolds might cost $15,000 and a single-cavity aluminum mold, $5000. But when you add the prototype tool to the required production tool, a customer will spend more than RapidMolds’ price and, more importantly, lose time in the overall process. And the more parts that are required from the prototype tool, the more cost effective RapidMolds becomes.

Borne believes customers will see a greater return on their investment as they learn the value proposition of building a production mold with a prototype lead time, rather than a prototype mold and a future production mold. “A lot of companies are starting to realize that they can get a steel tool with all the tolerances and dimensional accuracies required in the same amount of time as a prototype mold, and when they crunch the numbers, it becomes evident that a prototype doesn’t save them a lot,” he says.

“We’re not a perfect fit for every job. But I can say that in spite of a down economy, we’re booming. Word’s getting our about our lean, quick, and accurate process, and at the end of the day, they get something much more valuable—a steel production tool.” —[email protected]

WEB EXTRA

Rapid tooling with DMLS cuts time, costs

Rapid tooling (RT) using SLS (selective laser sintering) can provide prototype molds quickly and cost effectively, but they tend to be limited in the number of parts that can be molded from them. However, some companies that work in the rapid manufacturing (RM) processes say that, depending on the plastic used, they have gotten upwards of 50,000 parts.

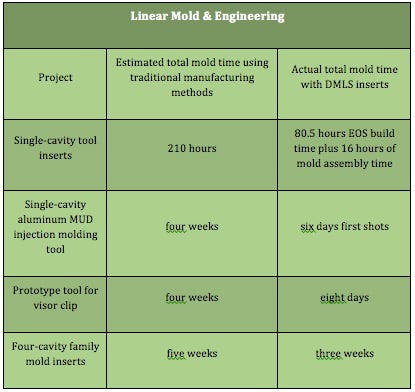

A recent additive process is Direct Metal Laser Sintering (DMLS) from EOS GmbH. Linear Mold & Engineering (Livonia, MI) was an early adopter of DMLS, and has been on the cutting edge of RM for several years.

|

In September 2008, Linear released data that it had been compiling showing the dramatic savings with DMLS for tooling and mold inserts. The company compared manufacturing times for creating molds and mold inserts in DMLS against traditional machining processes. Data were assembled over two and a half years of costing out more than 50 commercial tool and mold projects across a wide variety of industries. The results showed that, for many applications, DMLS significantly reduced production time and costs. Cost savings were between 15% and 30%, depending on part complexity.

John Tenbusch, president of Linear, says, “Given the high cost of materials and energy these days, we are always on the lookout for savings and efficiencies. Often, when we compare our production times between laser-sintering and other manufacturing methods, using DMLS is the obvious choice.” —[email protected]

|

About the Author(s)

You May Also Like