Leonhard Kurz also will present metallization options with indium and haptic effects using digital printing.

January 8, 2021

Leonhard Kurz will be presenting innovations in the field of plastic decoration at this year's all-digital CES innovation show, which will take place online due to the coronavirus pandemic. The focus is on the consumer electronics and automotive sectors.

Kurz is presenting antibacterial surface treatment and metallization options with indium. This makes it easy to equip devices with the new 5G mobile phone standard. A patented technology, which enables surfaces to be equipped with haptic effects using digital printing, will also be presented for the first time to a wide audience.

Spurred on by the global pandemic, demand for surface finishes that eliminate bacteria and viruses continues to rise sharply, a development that Kurz is responding to this year with the innovative Biofense process. Another innovation has been added to the in-mold decoration (IMD) process already in use, which ensures an antibacterial effect with a long-term impact on plastic surfaces. This was confirmed by the Fraunhofer Institute in accordance with ISO 22196.

The new anti-bacterial surface finish targets adoption in notebooks, mobile phones, and light switches, as these have a high bacterial density due to frequent touching. The same applies to surfaces in the interior of vehicles: Touch displays and instrument panels can also be equipped with the new IMD Biofense surface.

The metallization options based on chrome, aluminum or tin, which are also offered by Kurz, are now being expanded to include the indium option. Indium decoration more accurately matches the color shade of hard chrome, which is traditionally achieved through electroplating. The plasma vapor deposition (PVD) process used makes it much more environmentally friendly and less harmful to health during processing.

The new process also meets technical requirements of the automotive industry and is suitable for use in exterior and interior areas. The fact that indium is permeable to radar and 5G beams further expands the scope of application. For automobile manufacturers, this product feature is just as important given the concepts of autonomous driving. The same is true for manufacturers of consumer electronics who want to serve the trend towards smart consumer products equipped with antenna technology, such as mobile phones, tablets or, for example, loudspeakers.

Kurz innovation makes it possible to reconcile the technical progress of electronic products with 5G support and the visual enhancement through metallization. There are no limits to individualization: Indium is suitable for high-gloss surfaces as well as matte, semi-matte and brushed designs, can be combined with patterns, can be backlit and is therefore suitable for Shytech (black panel) designs. This makes the innovation a true all-rounder in the metallization of plastic surfaces.

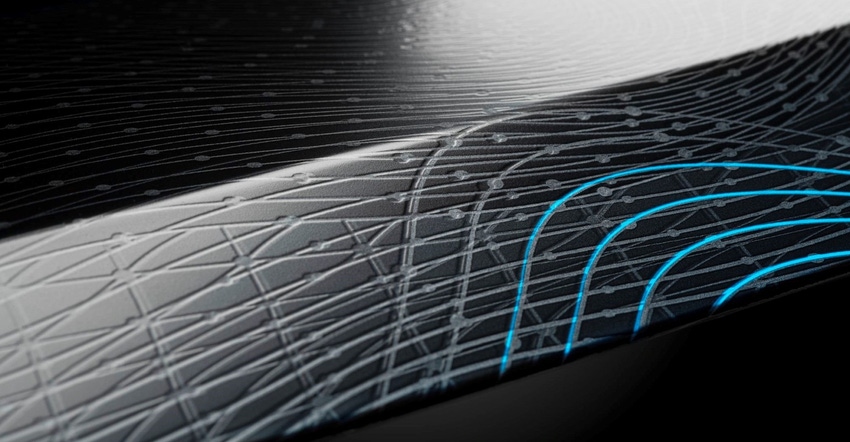

In the future, it will be possible to transfer tactile structures to plastic surfaces through digital printing, thanks to IMD decoration. By using both sides of the carrier film in this patented process, the decorative surfaces and the structure can be transferred in one process step without influencing the outstanding performance of the surface protection (protective layer). The additional use of digital printing technology enables the individualization of end products, even for smaller quantities, paired with the efficiency of the IMD process.

The digital CES show runs from Jan. 11 to 14. Register here to attend.

About the Author(s)

You May Also Like