Manufacturers are always looking to improve profitability and moldmakers are no different. Yet, according to Jim Hensiek, director of business development for Creative Blow Mold Tooling (Lee's Summit, MO), most companies are missing out on an important opportunity for improved profitability simply because they are unaware of the profit contributions their supplier can bring.

September 8, 2014

Manufacturers are always looking to improve profitability and moldmakers are no different. Yet, according to Jim Hensiek, director of business development for Creative Blow Mold Tooling (Lee's Summit, MO), most companies are missing out on an important opportunity for improved profitability simply because they are unaware of the profit contributions their supplier can bring.

"At Creative Blow Mold Tooling, it's all about building our relationships, growing the partnership that results in an effective supply-chain timeline for our customers," Hensiek said. "If we can help make our customers more profitable, generate a greater ROI and beat the expectations of the marketplace, that's what we do and what we're about."

The goal for manufacturers is to develop a supply chain that maximizes their success in the market. For OEMs that produce plastic products or plastic components for their products, the mold manufacturer is the lead vendor. Not only is it critical for the OEM to have its supply chain in alignment with schedules (product release dates, etc.) and financial goals, but it's just as critical for the mold manufacturer to have the links in its supply chain functioning on-time and on-budget.

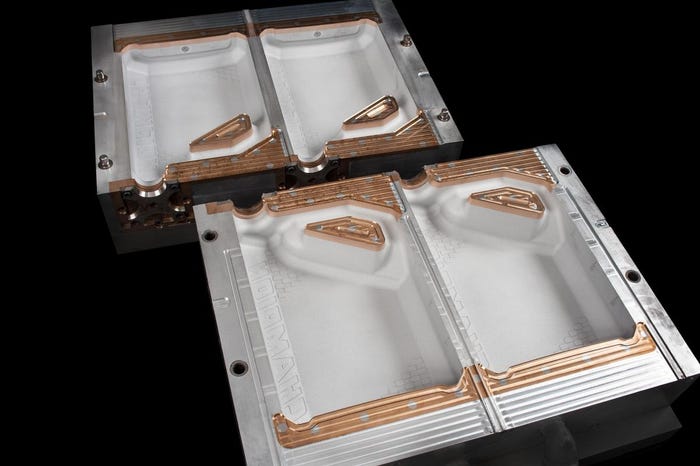

|

Blow mold built by Creative for a customer in the consumer products industry. |

"In order to meet customers' ever shrinking lead time requirements, the moldmaker must avoid bottlenecks that can result in delays in the mold build,"Hensiek said. "Because each mold design is unique, we can't maintain a huge inventory of mold components or mold materials in stock. So, developing good relationships and partnerships with our suppliers is critical to our ability to deliver completed projects on time."

For that reason, Creative's investments are focused on growing the partnership business model, not only with its suppliers but with customers as well. "Our approach with our customers is simple and straightforward: to be consistent and predictable in establishing and maintaining an environment of trust," Hensiek said.

Being a critical part of their customers' supply chain, Creative is well aware of the fact that the OEM's success is dependent on its suppliers. "When a new mold design is needed, our five-member design engineering staff is available and quick to respond, helping to reduce the supply-chain timeline," Hensiek said. "Leveraging our product design talent, our engineering expertise and our experience with various machine platforms, we can create tooling in the shortest timeline possible that will effectively blow-mold parts. This collaboration with customers, as equal partners, reduces costs and improves the quality of the end product."

True success in a mold program requires that Creative work collaboratively with its customers throughout the process, from the beginning of each new project. Hensiek explained, "At Creative, the more knowledge of the project we have up front, the more efficiently we can move through the design approval process and the more successful we are in shortening the project timelines, and helping our customers be first to market resulting in a greater ROI."

|

Samples of the types of bottles Creative blow molds. |

Creative Blow Mold works with each customer to maximize their plant's productive man-hours and the company's ROI by getting information about the plant's machine platforms at the start of the collaboration. This allows Creative Blow Mold to reduce the engineering design time for the project and compress the supply chain timeline as well. "With this information and working with several projects, Creative has been able to reduce unit mold - the mold used to make sample bottles - manufacturing time by seven days," Hensiek said. "Bottle samples can then be tested to verify design, function and expectations of the bottle, while the production molds are being built. With communication being the key component in the collaborative efforts, the manufacturing time for the production mold was reduced by an additional seven days. On this project, understanding the importance of ROI for our customers allowed Creative to improve the supply-chain timeframe by 14 days, getting to profitability sooner."

Building an effective and efficient supply chain through a collaborative environment required a commitment from all parties in which behaviors consistently match the expectations. "As we collaborate to achieve our combined goals, there may be a need to think differently, supporting the innovation process, to achieve success," Hensiek said. "In the end, we want to be an extension of our customer's team, enjoying and sharing the success of our collective efforts to deliver quality and innovative end products to the marketplace. Helping both teams win will get both parties to the goal line quicker."

About the Author(s)

You May Also Like