Sponsored By

News

Bioplastics-NewsStream-FTR-PT.png

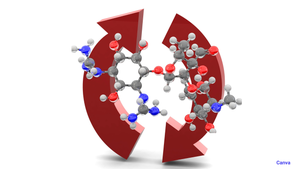

Biopolymers

Bioplastics News StreamBioplastics News Stream

Composting conundrum, biopolymers and synthetic biology, next-best alternative, PEF R&D, PLA/LAHB blend, compostable coffee pod.

Sign up for the PlasticsToday NewsFeed newsletter.