A collaboration to improve the efficiency, performance and sustainability of packaging applications between Reifenhauser Kiefel Extrusion and DuPont Packaging & Industrial Polymers, has resulted in a material and cost-saving medium barrier 9-layer film for thermoforming applications.

July 24, 2014

A collaboration to improve the efficiency, performance and sustainability of packaging applications between Reifenhauser Kiefel Extrusion and DuPont Packaging & Industrial Polymers, has resulted in a material and cost-saving medium barrier 9-layer film for thermoforming applications. Key to a weight reduction of up to 20% and improved packaging performance over traditional 7-layer PA/PE structures are Reifenhauser's versatile 11/9-channel Evolution barrier blown film technology and a new high stiffness DuPont Surlyn ionomer sealant resin, which allows for sealing at lower temperatures and provides a broad operating window.

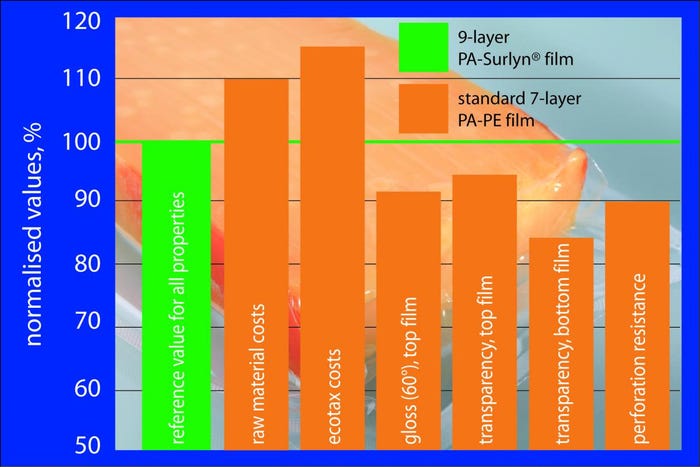

Other advantages of the new material include superior perforation and abrasion resistance as well as improved fat barrier, making the new film ideal for vacuum packs containing hard and sharp products, such as mature cheese or meat with bones or smoked ham. A financial benefit to the new material is that the material costs for the new PA/Surlyn structure are around 10% lower compared to the 7-layer PA/PE structures. A further financial benefit results from a reduction of up to 20% in 'ecotax' due to the reduced packaging weight.

Summing up these savings, claims DuPont, is the additional investment for a 9-layer blow film line that will pay back in the short term because the cost for a system, including nine extruders and blending units as well bigger units and a bigger die head, are just 10-15% higher than those for a 7-layer line. Taking into account just the resin related cost savings of 10%, the payback time for these additional costs will be less than six months. This can be further accelerated, if higher sales prices for the superior films can be achieved.

Additionally, DuPont and Reifenhauser labs reveal that testing shows the new 9-layer structure provided a gloss gain of 10% and a 13% higher transparency over currently used films, and "exhibited improved thermoforming performance."

Additionally, DuPont and Reifenhauser labs reveal that testing shows the new 9-layer structure provided a gloss gain of 10% and a 13% higher transparency over currently used films, and "exhibited improved thermoforming performance."

Cost-efficient production of the new multi-layer thermoformable 9-layer structure has been made possible by the versatility and precision of Reifenhauser Kiefel's Evolution Ultra Range extruders, according to the company's information. Developed for easy processing of complex film structures with all kinds of resins, they provide "outstanding flexibility" in terms of choice and amount of high-performance polymers, including high-barrier grades, adhesives and sealants, allowing use of the most suitable materials at minimum costs.

Reifenhauser Kiefel Extrusion GmbH is a member of the Reifenhauser group that consists of six business units and over 1,200 employees. The company claims to be the largest extrusion network in the industry. The company specializes in blown film extrusion systems and peripheral equipment for the production of flexible films ranging from simple mono layer up to sophisticated 9-layer barrier film lines for a wide variety of applications.

DuPont Packaging & Industrial Polymers manufactures an extensive mix of adhesive, barrier, peelable lidding and sealant resins, and provides a globally networked development team to work with customers on packaging programs that help protect the product, environment; improve shelf appeal, convenience; and reduce cost in the food, cosmetics, medical products and other consumer goods and industrial packaging industries.

About the Author(s)

You May Also Like