Sponsored By

Blow Molding

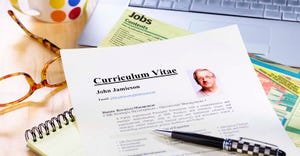

Coca-Cola's new lightweighted bottles.

Packaging

How Coca-Cola Bottles Lost WeightHow Coca-Cola Bottles Lost Weight

Fifteen questions answered about a complex project involving the brand’s small PET bottles that was three years in development.

Sign up for the PlasticsToday NewsFeed newsletter.