Metal replacement continues to be a dominant theme in plastics. EMS-Grivory, the Swiss specialist in this area, was showcasing a number of innovations with its metal-replacing high-performance polyamides last week at the Fakuma trade show in Friedrichshafen.

October 21, 2014

Metal replacement continues to be a dominant theme in plastics. EMS-Grivory, the Swiss specialist in this area, was showcasing a number of innovations with its metal-replacing high-performance polyamides last week at the Fakuma trade show in Friedrichshafen. Pride of place was reserved for applications featuring their long-fiber reinforced thermoplastic materials - one of the most important trends in the plastics processing industry today - and which, said the company "are perfectly suited for high-quality metal replacement applications, as they offer metal-like strength values despite extremely low weight."

They do so by forming a skeleton-like structure inside the finished part, thus increasing the mechanical properties of the component. In this way, stiffness and strength values can be achieved, which are significantly higher than those of thermoplastics reinforced with short fibers, without impacting on other properties, such as chemical resistance or surface quality. The long fibers also reduce creep and increase dimensional stability.

They do so by forming a skeleton-like structure inside the finished part, thus increasing the mechanical properties of the component. In this way, stiffness and strength values can be achieved, which are significantly higher than those of thermoplastics reinforced with short fibers, without impacting on other properties, such as chemical resistance or surface quality. The long fibers also reduce creep and increase dimensional stability.

In addition, the thermal properties of these materials are markedly better at high or low temperatures. This means that components can be made which, for example, must be resistant to high thermo-mechanical loading while having excellent surface quality.

Currently, EMS-Grivory offers long-fiber reinforced polyamides in five product families: Grivory HT, Grivory GV, Grilamid L, Grilamid TR and Grilon TS. All these materials can be processed using conventional injection molding equipment.

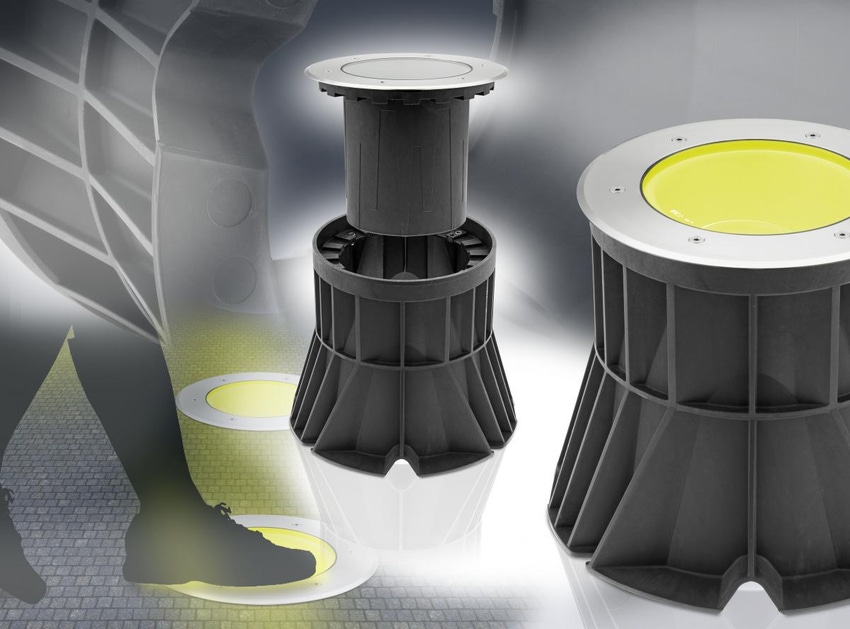

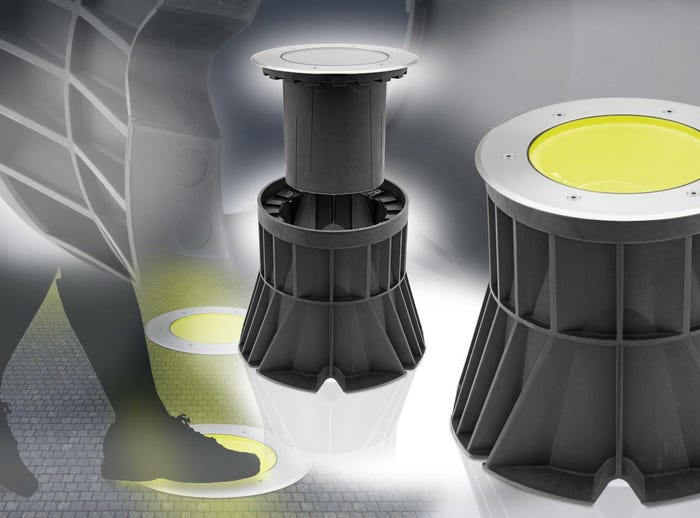

Although the mechanical properties and stiffness-to-weight ratio means that this is a technology that offers huge benefits for the automotive industry, the advantages offered by long fiber technology are not limited to vehicles alone. Architectural lighting specialist ERCO selected Grivory GVL-4H, a long-fiber reinforced design material to replace the metal that was previously used for the housing of its TESIS in-ground exterior light. The problem with the stainless steel housing was both its weight and the fact that it corroded due to contact with the ground. Moreover, it is not unusual for heavy-duty vehicles to drive over these lights, which meant the material used needed to be extremely tough. Tests on the light housings made with Grivory GVL-4H showed compressive strength of 17 tons, although only a value of 5 tons was required. As these lighting systems are very popular with ERCO's customers and the material more than met all expectations, further development projects with this material are already underway.

EMS was also showcasing another metal replacement application, the new, heavy-duty stirrup developed in France made of Grilon TSGL-0/4. This material can effectively transfer the dynamic loading of the lower edge during horse jumping and is resistant to even the hardest knocks. Besides achieving a significant weight reduction, the component is sheathed with an elastomer providing a safe forwards hold but allowing riders to slip their foot quickly out of the stirrup.

About the Author(s)

You May Also Like