Schwertberg, Austria—Borrowing a technology concept from Formula One where the race cars capture braking energy for use when extra power is needed, Engel has filed patents on a similar technology for injection molding machines.

June 5, 2013

Schwertberg, Austria—Borrowing a technology concept from Formula One where the race cars capture braking energy for use when extra power is needed, Engel has filed patents on a similar technology for injection molding machines.

Stefan Engleder, chief technology officer of the Austrian injection molding and automation supplier, said Engel is investigating the concept for its line of e-speed injection molding machines, capturing energy from the deceleration of the moving platen.

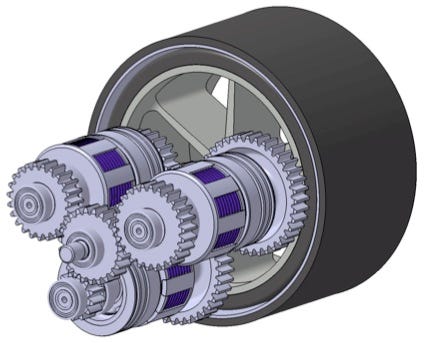

KERS flywheel |

Engel's concept is derived from the Kinetic Energy Recovery Systems (KERS) utilized in the braking systems of Formula One race cars. |

Speaking at his company's pre-K press conference from Engel's Schwertberg, Austria headquarters, Engleder noted that much like a race car braking as it enters a curve and then accelerating out of the turn, the injection molding process entails repeated accelerating and then decelerating. "Looking at acceleration," Engleder said, "you actually need energy. First it's taken from the grid, but this is not sufficient, so the new system also takes energy from the kinetic energy storage. During deceleration, the machine recovers kinetic energy, and some energy is also recovered into the grid."

Among the advantages, Engleder said the machine will have less overall energy consumption; less heat loss; and less connected load, since a portion of the power needed to operate the press is taken internally and not from the grid.

In Formula One, kinetic energy recovery systems (KERS) are electrical or mechanical in design, utilizing either a battery or a flywheel. Engleder said Engel will utilize a flywheel design, for which it has filed a patent. He also said the company is looking at extending the technology to other machine series, noting that the system's ability to generate some of the needed power can result in a reduced drive and motor requirements for the injection molding machine.

About the Author(s)

You May Also Like