The discoloration and brittleness of materials following sterilization have long been bugaboos of medical device design engineers. A remedy exists. Ensinger North America (Washington, PA), which supplies plastic stock shapes to the medical sector, recently began a series of successful extrusion trials using Ultem HU1004, a medical-grade polyetherimide, from Sabic Innovative Plastics. The material was deemed to have significant advantages over competitive products in third-party tests conducted on behalf of Sabic.

April 3, 2014

The discoloration and brittleness of materials following sterilization have long been bugaboos of medical device design engineers. A remedy exists. Ensinger North America (Washington, PA), which supplies plastic stock shapes to the medical sector, recently began a series of successful extrusion trials using Ultem HU1004, a medical-grade polyetherimide, from Sabic Innovative Plastics. The material was deemed to have significant advantages over competitive products in third-party tests conducted on behalf of Sabic.

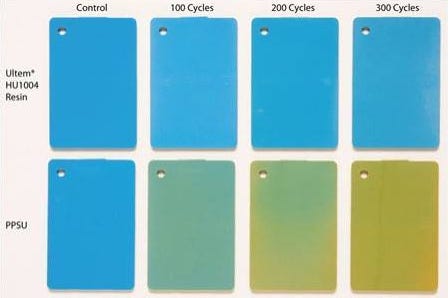

Tougher than standard grades of Ultem, HU1004 notably withstands low-temperature hydrogen peroxide gas plasma, or Sterrad, sterilization. The aforementioned independent tests reportedly revealed significant performance and aesthetic advantages, particularly in ductility and color stability, compared with alternative materials used in medical applications.

Medical-grade Ultem resins are certified to ISO 10993 and comply with USP Class VI requirements. Engineered with enhanced chemical resistance to lipids and disinfectants, the resins are available in opaque and transparent colors and are suited for thin-wall designs, according to Sabic.

|

A comparison of the discoloration of Ultem HU1004 and polyphenylsulfone |

"Ensinger has successfully extruded Ultem HU1004, and is actively working with medical device manufacturers who are interested in broadening the sterilization capabilities of their products," says Bruce Dickinson, Marketing Manager, Ensinger North America.

Ensinger North America processes high-performance engineering plastics at five facilities in the United States. The company is a subsidiary of Ensinger GmbH, headquartered in Nufringen, Germany, which was founded in 1966 and is specialized in the development and production of high-performance and engineering thermoplastics, extruded and cast semifinished products, machined and injection molded finished parts, profiles and tubing, and construction products.

About the Author(s)

You May Also Like