Following an investment of approximately six million Euros, Evonik Industries AG's new production facility for Rohacell structural foam came on stream at the company's Darmstadt site at the end of 2013. The new facility increases the polymerization capacity at the site by 50 percent. Moreover, the extensive automation of the polymerization process has cut cycle times almost in half.

February 4, 2014

Following an investment of approximately six million Euros, Evonik Industries AG's new production facility for Rohacell structural foam came on stream at the company's Darmstadt site at the end of 2013. The new facility increases the polymerization capacity at the site by 50 percent. Moreover, the extensive automation of the polymerization process has cut cycle times almost in half.

Rohacell is a structural foam that is used in fiber-reinforced composite parts for lightweight applications and lightweight sandwich constructions. The foam is produced by thermal expansion of a co-polymer sheet of methacrylic acid and methacrylonitrile. During the foaming process, the copolymer sheet is converted to PMI (polymethacrylimide). Rohacell  is halogen free, has a very homogeneous cell structure and isotropic properties. The cell sizes can be tailored to all processing methods. The 100 percent-closed-cell foam takes up resin only in the exposed cut cells at the surface. This prevents excess resin from infiltrating further into the foam, which would add unnecessary weight.

is halogen free, has a very homogeneous cell structure and isotropic properties. The cell sizes can be tailored to all processing methods. The 100 percent-closed-cell foam takes up resin only in the exposed cut cells at the surface. This prevents excess resin from infiltrating further into the foam, which would add unnecessary weight.

The foam boasts excellent mechanical properties over a wide temperature range, even at low densities, high temperature resistance up to 220°C and excellent dynamic strength.

The most important market segments are aerospace and lifestyle, as well as automotive engineering and wind energy.

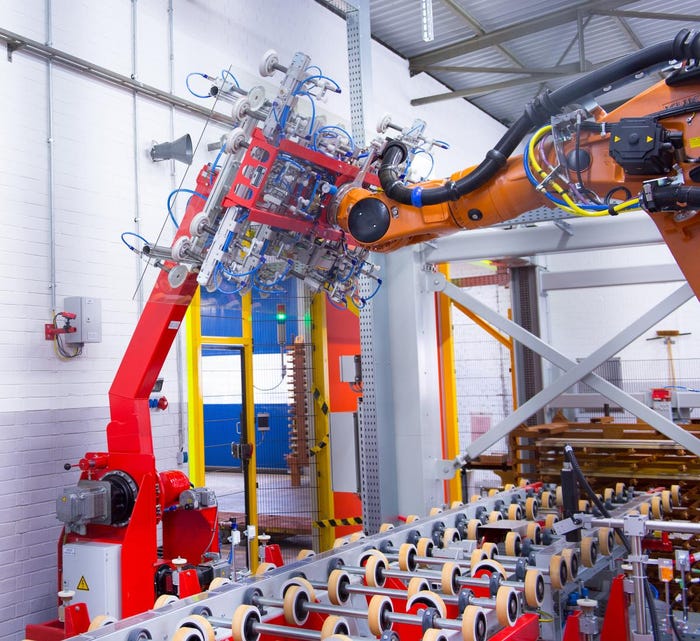

Evonik invested in the new facility, complete with efficient robot technology for shorter cycle times and higher capacity, in order to be better able to meet growing market demand.

Stefan Plaß, head of the growth line advanced technologies, looks toward the future: "Rohacell is expanding into ever larger serial applications. Our customers expect highly efficient and economic production processes from us. Only in this way can we make lightweight construction with Rohacell attractive for large quantities and new applications. We're making an important step in this direction with automating the polymerization, but we are also planning further automations and optimizations in the production process."

About the Author(s)

You May Also Like