After the plastic is hot enough to come out of the die, the heat has to be taken out without distorting product dimensions. Here’s how.

January 12, 2023

This month’s extrusion column is about cold, appropriate for January. Often in extrusion it’s cold and wet, which is even more appropriate this year.

To get a thermoplastic to soften enough to extrude, it has to be heated — the thermo in thermoplastic. Before going further, let’s get two things clear.

First, heat is a form of energy, so it can be counted and measured. Energy has many forms, but it doesn’t appear or disappear. No magic. It can be measured in calories — the heat that raises one gram of water 1°C. That’s a tiny amount, so it’s common to use capital letters — Calories (Cal) or Kalories (Kal or Kcal) to represent 1000 small calories. If you use joules: 4.2 joules = 1 calorie.

The numbers have been known for a long time, but they are sometimes ignored or avoided where counting is unwelcome. Same for people who don’t want to count food calories, which is unscientific but permits other pleasures of eating, such as taste and the “freedom” to follow impulse and image, such as, “If it’s green, it’s good for you.”

We scientists can enjoy food, too, even if we count calories: 9 Kcal/gram of fats or oils and 4 Kcal/gram of proteins and carbohydrates (starch, sugars), if digested and available. Yes, fats are nutrients as energy sources, and proteins are the same as starches and sugars, but public image says otherwise. Water — 80% for meat and variable in veggies — is also good for you but not a source of energy. So, it doesn’t count. The internet and food labels are full of this info, but remember it’s per gram, so how much you eat matters. Around 30 grams = an ounce and 454 grams = 1 pound, so don’t let the grams stop you.

The second item to get clear is temperature scales. We need to speak both C and F, and if we have a gauge or data point, know what the units are. It’s easy: 5°C = 9°F and 0°C is 32°F (water freezes to ice, same molecules but organized structure). Fahrenheit (F) invented the thermometer in 1717, but Celsius (C) based the scale on water freezing and boiling in seaside Sweden, same as in sea level USA (it varies with altitude, but he didn’t know that).

To understand cooling, you must understand heating

Back to plastics. To understand cooling, we must understand heating. There is no such thing as cold — cooling means removal of energy. It takes around 138 Kcal (0.16 kWhr) to heat 2.2 lb (1 kilogram) of low-density polyethylene (LDPE) from a room temperature of 73°F (25°C) to an extrusion temp of 410°F (210°C). That’s about 0.61 Kcal per lb. These numbers are ideal, but in the real world there are real losses; if I have no other info, I assume the double of this is needed. It’s still usually too little to worry about cost, but not about overheating.

Most of this energy comes from the motor as it overcomes friction to move the screw forward in the sticky melt. Some comes from die heaters, and also barrel heaters for high-temp plastics like PET and the nylons. Those numbers include both raising temperature and breaking the crystallinity, which is around 40% for LDPE.

It’s hard to find such data even on the internet. I use Rao & O’Brien (Hanser, 1998), and polymer scientists will know other sources, but extruders don’t worry much about it, as most machinery can add more than enough heat. It does lead to a common misunderstanding, though, that most heat comes from the barrel heaters, because those are the temperatures we regulate with both heaters and air or water cooling.

The importance of rear-barrel temperature

But the prominence of barrel heat is true only for very small machines, or any machines that run slowly, some extrusion-coating, some twins, and high-temp polymers, as noted above. Heaters are needed for startup and useful to hold things steady but usually not a major source of heat. Rear-barrel temperature is critical for another reason: It controls pellet slip on barrel walls in the first zone(s) and, thus, controls the inpush/output rate.

Grooved-barrel extruders are an important special case, often used for high-density (HD) PE. If you have one, learn more about how it works. The first zone is water-cooled to prevent sticking and melting there. With plain barrels, too, there may be cooling to avoid sticking in the feed entry passages, but unless there are grooves, this is seldom closely controlled.

Product cooling

After the plastic is hot enough to come out of the die, the heat has to be taken out without distorting product dimensions. There are three main coolants — water, air, and a cooled metal surface such as a roll. Heat-transfer fluids are used where temperatures above 100°C are wanted, such as inside some rolls for sheet lines.

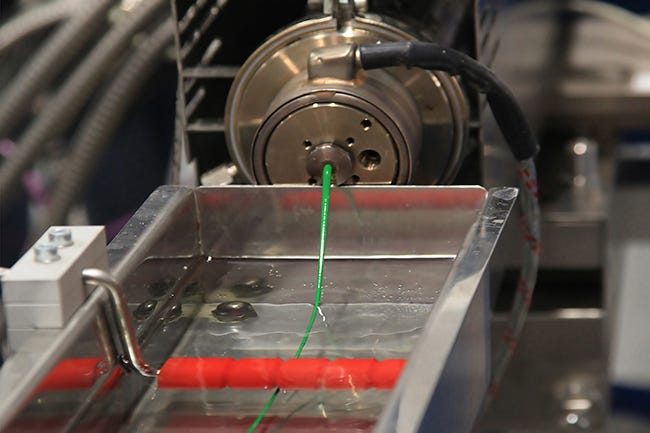

For most profiles, including pipe and tubing, water is enough, with a sizing device on entry and long water tanks (troughs) that feed a puller, cutter, or winder. A printer may also be in that line.

|

A water trough is often sufficient to cool most profiles. |

Such products are typically cooled with water on the outer surface of the emerging melt. Note that some polymers float and all tubes will push up if immersed, so all-around sprays allow all-around uniformity. With full immersion there is full contact, but some pushdown may be necessary and may distort the product.

Thickness matters, as heat moves slowly through plastic, and in proportion to the temperature difference, so thicker = slower. All plastics shrink when cooled, especially the semicrystalline ones. If cooled too fast, there will be more stresses in the product, which may or may not matter (you can test this with heat-shrink).

Sizing devices may have separate cooling, even those that can vary product dimensions on the fly. A ring of water can be applied to the product as it enters the sizer to cause a little shrinkage and lubricate its entry.

Vacuum may be used in sizing, either to pull the hot plastic out to fixed metal dimensions (sizing sleeve) or, with hollow products like pipe, to reduce pressure in the air space so the air pressure inside the hollow product pushes it out to conform to the sizer hardware. Too much vacuum may slow or stall the sliding motion, so good pressure control and lubricious materials are needed.

A word about compounding

Compounding and some filaments may be extruded downward into a water tank. Level adjustment controls die-to-water distance, and die, melt, and water temperature all matter.

The highest-output compounders may have internal cooling, where water is inside and under a round die with a spinning cutting blade inside that throws the hot pellets into the water stream. Line dies — one or two rows of holes — are usually drawn as strands through an external water tank, although strands from round dies can be so cooled, as well.

Blown thin film

The biggest use of air as coolant is in blown (tubular) thin film, where a hot tube comes out of the die upward (a few go downward or sideways) and an air ring blows air on the emerging surface, which is also expanding and thinning from internal air pressure. The outside air may be cooled to get faster production. As this is a big market, there are many variations on this principle, notably internal bubble cooling and downward extrusion with water plus air as coolants. Irises strip the hot air from the surface so cooler air can come in to gain speed.

Metal roll cooling

Metal roll surfaces are common for cooling most flat sheet, extrusion coating, and some film. Most common for sheet are multi-roll stacks; most are set vertically, and a few are at an angle, even horizontal, and may allow the melt to fall into a nip. Thin films and coatings may have only one big cooling roll which the plastic contacts as it leaves the die (distance adjustable).

The verticals often run down the stack, with the plastic lower surface hitting the middle roll first, going around it, and then cooling the other surface on the roll under the first. The top roll doesn’t cool much but applies pressure to the emerging extrudate; it can also preheat, emboss, and/or apply a laminating layer. Where the top surface is critical, the system can run up the stack, keeping the first cooled surface always on the upper side and, thus, not contacting support rollers.

In roll cooling, water temperatures are closely controlled with heat exchangers, if needed. Pay attention to center-end differences in die temperatures, which in flat dies may be easier to handle in/on the die (gap, spot insulation and heating, and settings) than in the cooling. Such die changes may be useful for other dies, too, not only flat ones, and all may need a narrow-angle infrared thermometer.

Edges of flat products that are to be trimmed may be enclosed and air-cooled or run thinner to avoid slower cooling and send less trim to regrind. Also, air fans over exposed surfaces (including undersides) can augment cooling.

Blow molding

Much blow molding is fed by extruders, and some of the prior comments apply, especially those dealing with pipe. Cooling, however, is in the molds and is more related to injection molding than pipe extrusion.

Cooling fluids may be refrigerated for better cooling, but if too cold, their conveying passages may condense water from the atmosphere and get warmer, so insulation may well pay for itself. Chilled air for blown film is a significant operating cost unless well-managed (with temperature measurements and known desired values).

Feed temperature

Feed temp is often neglected, and is especially important if feed is stored outdoors. Such variation (day-night or seasonal or sun-caused) can be avoided by preheating the feed even if not necessary to remove moisture, as the uniform feed temp may be enough of an advantage to justify its cost. Insulate the hopper and maybe some transmission lines to reduce radiation loss. Powder feed is a real but surmountable problem.

|

Insulating the hopper is an option for maintaining uniformity of feed temperature. |

Preheating is also a remedy for systems where the motor doesn’t generate enough heat and the barrel and die can’t compensate or aren’t fully available.

Precooling the feed may be useful to keep feed temperature constant, but is rare, as it just means more heat is needed in the actual extrusion.

Reuse of cooling energy

Some lines can direct hot air from around the barrel up into the feed. Not common, but attractive in very cold climates or where power costs are unusually high. In much of North America, power costs are low enough to discourage such savings, but that may change in the future, or even now if management is trying to reduce dependence on grid electricity. Someone should know how much would be gained, and shouldn’t have to guess.

This can be done with cooling water, too, but there are fewer water-cooled extruders and cost savings alone may not justify it.

Reuse of heat from product cooling is not common but possible, and worth attention if it can raise production speed and you can profitably sell the increase. Efficiency of water-cooled lines can often be optimized by passing the product through cut-outs that remove the layer of hot water around the product and, thus, encourage flow of cooler water up close to the product surfaces.

Don’t forget post-cooling shrinkage, which may affect printing and trimmed dimensions. It’s not all over when you can stack or roll it, as some plastics shrink for hours or more after on-line cooling, and some of this depends on the speed of that cooling.

Screw cooling

Last but not least, many screws can be internally fluid-cooled during operation using a heat exchanger to ensure constant input temperature. That doesn’t get much heat out of the system, but it does improve mixing. It is reversible, needs no new machinery, but will reduce output per rpm. If increased screw speed can regain the loss, it’s a win-win.

Allan Griff is a veteran extrusion engineer, starting out in tech service for a major resin supplier, and working on his own now for many years as a consultant, expert witness in law cases, and especially as an educator via webinars and seminars, both public and in-house, and now in his virtual version. He wrote Plastics Extrusion Technology, the first practical extrusion book in the United States, as well as the Plastics Extrusion Operating Manual, updated almost every year, and available in Spanish and French as well as English. Find out more on his website, www.griffex.com, or e-mail him at [email protected].

No live seminars planned in the near future, or maybe ever, as his virtual audiovisual seminar is even better than live, says Griff. No travel, no waiting for live dates, same PowerPoint slides but with audio explanations and a written guide. Watch at your own pace; group attendance is offered for a single price, including the right to ask questions and get thorough answers by e-mail. Call 301/758-7788 or e-mail [email protected] for more info.

About the Author(s)

You May Also Like