Multiple nuts and bolts have been eliminated, accelerating gum space adjustment while improving accuracy and repeatability.

May 25, 2022

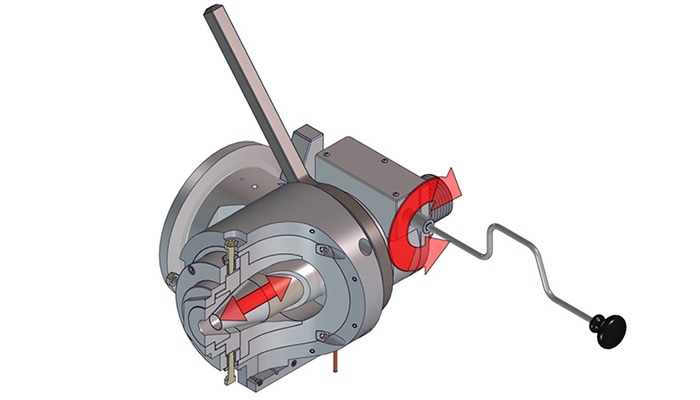

The new 500 Series extrusion crosshead with mechanically assisted gum space (MAGS) adjustment from Guill Tool & Engineering is designed specifically for the flow characteristics and unique processing challenges of elastomeric compounds.

A new method of gum space adjustment, MAGS allows the operator to make adjustments from a single point using a common socket wrench. The innovation eliminates the need for multiple nuts and bolts, which leads to faster adjustments. A visual indicator on the core tube allows the operator to see precisely how far the gum space has been moved, improving accuracy and repeatability.

The patented, hardware-free cam lock design means no time is wasted unbolting and re-securing fasteners for disassembly and re-assembly, said Guill. A half-rotation of the cam nut is sufficient for loosening and automatically extracting the deflector from the head body. The absence of undercuts on the deflector ensures easy removal of the deflector and accelerates cleaning and changeover operations.

The 500 Series also features the latest iteration of Guill’s center-stage concentricity adjustment system, which significantly reduces pressure on the tooling, allowing easier and more precise concentricity adjustments without loosening the face bolts. Easy-out inserts for the adjusting bolts allow simple replacement of locked or damaged bolts.

A cast aluminum liquid-fed cooling sleeve allows the user to switch out the cooling jacket in the event of a line obstruction, reducing downtime compared with traditional integrated cooling systems.

The addition of a newly designed flow inlet channel reduces shear and heat generated as the materials are being processed. This leads to lower head pressure, allowing the material to move through the head in a much more balanced and even flow.

The new 500 Series crosshead is a drop-in replacement for most existing NRM extrusion lines; the crosshead design also can be adapted to fit any extruder design or line layout.

All Guill crossheads are furnished with a tool kit for assembly and disassembly as well as a detailed instruction manual. Guill engineers will gladly assist users in the implementation and operation of the new 500 series crosshead.

You May Also Like