The version includes several new features, including accurate simulation of extrudate cooling and corresponding shrinkage in the complete cooling system.

November 11, 2020

The latest version of polyXtrue software for the design of polymer extrusion dies has several new features, announced Plastic Flow.

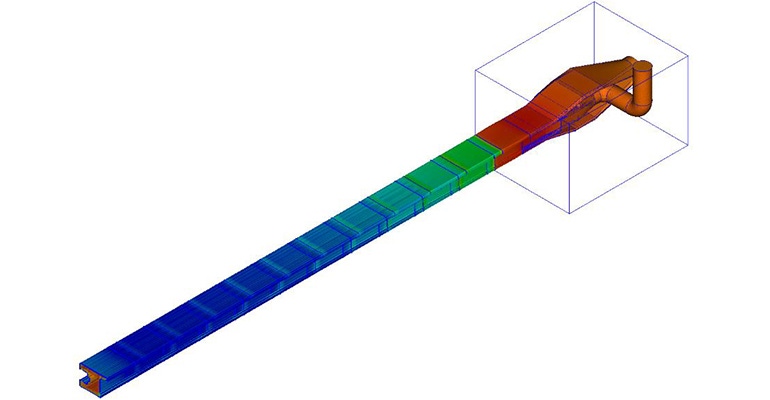

PolyXtrue software provides engineers insight into the performance of extrusion dies in the early design stage. It captures accurate quantitative information on the flow inside the die as well as in the extrudate beyond the die exit. PolyXtrue also has the unique capability of accurately predicting the distortion, shrinkage, and temperature of the extrudate and determining the layer structure in multi-layer co-extruded products.

New software features include the following:

Accurate simulation of extrudate cooling and corresponding shrinkage in the complete cooling system. The system accommodates 20 calibrators and sizers. Two different temperature zones are allowed between calibrators, and one of the temperature zones can be a wiper between a water tank and the calibrator. Ten different temperature zones are possible between the die exit and first calibrator and after the last calibrator.

Calibrator profiles can differ from the die exit profile, allowing extrusion of complex profiles from relatively simple die geometries.

Die geometries can now be imported in native Creo file formats in addition to SolidWorks and Inventor formats.

About the Author(s)

You May Also Like