These projects, some of them epic in their dimensions, showcase the advantages of plastic pipe in several infrastructure projects, both here and abroad.

May 29, 2021

The announcement by the Plastic Pipe Institute (PPI) of the winners of the annual Projects and Members of the Year program couldn’t have come at a more propitious time. As the Biden administration and Senate Republicans haggle over the scope and price tag of the infrastructure plan, the PPI showcases some of the epic achievements realized in the United States as well as abroad. When President Biden first unveiled his $2.2 trillion plan, I wrote a piece arguing for the role that plastics could play in “building back better.” Well, here are some concrete — or should I say plastic — examples.

PPI Building & Construction Division Projects of the Year (two projects shared this award)

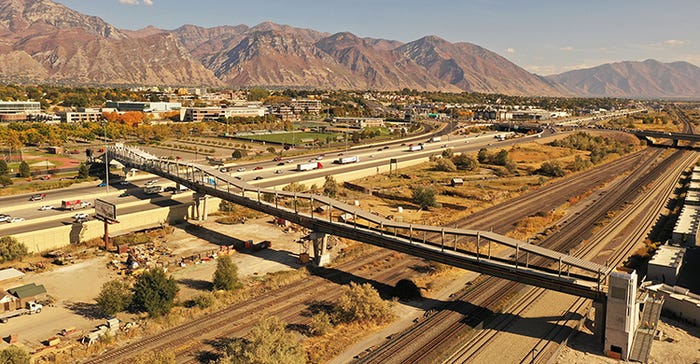

The Utah Valley University Pedestrian Bridge Snow and Ice Melting Project; PPI member companies: Rehau (Leesburg, VA) and Uponor Inc. (Apple Valley, MN)

|

The new 970-foot pedestrian bridge at the Utah Valley University (UVU) campus needed a reliable snow- and ice-removal system that didn’t involve salting or sanding the surface or moving equipment across the structure. The 305-foot-long, 17-foot-wide elevated bridge section suspended up to 35 feet in the air used some 35,000 feet of ⅝-in. Rehau Raupex O2 barrier PEX tubing for snow-melting loops embedded in the concrete pathway. The PEX tubing is supplied with heated antifreeze through 1,900 feet of 2.5 to 4 in. Uponor PP-RCT supply-and-return piping. The bridge is the first large-scale use of Uponor PP-RCT in North America.

Texas Military Base, Training Center 5 and 6; PPI member company: Asahi/America (Lawrence, MA)

|

The large, multi-storied facilities at the Texas Military Base required large-diameter pipe and fittings to move water effectively throughout the campus. Installation locations included crawl spaces, underground, and in riser locations. The project’s piping ranged in size from 4 to 18 in. and consisted of both SDR 11 and SDR 17 wall thicknesses. More than 6,000 feet of Asahitec PP-RCT pipe was used for hot and cold potable, non-potable, and chilled water, plus HVAC heating water and HVAC condenser water.

Asahitec PP-RCT was used instead of carbon steel pipe because polypropylene piping provides long-term performance and maintenance advantages. Because of its light weight, ease-of-maneuverability, and faster and safer welding methods, installing PP-RCT provided several benefits to the installers, writes PPI.

PPI Energy Piping Systems Division Projects of the Year (two projects shared this award)

Crestwood Equity Partners: Delaware Basin Saltwater Network Buildout, West Texas; PPI member companies: Dow Chemical Co. and Performance Pipe

|

The Delaware Basin Saltwater Network Buildout project brought a high-temperature saltwater disposal system to the Delaware basin using more than 88,000 feet of 12-, 18- and 20-in. PE-RT high-density (HD) PE. Because of the lack of infrastructure and a boom in drilling, a high number of trucks were required to transport the saltwater to the disposal units. The pipe network provided a way to move the salt water, typically between 140 and 180°F. The high temperatures left the engineers with expensive options to cool the produced water, or to find a corrosion-resistant pipe that could handle the temperatures. They identified Performance Pipe’s PlatinumStripe 1800 Series manufactured using Dow Intrepid 2499 Polyethylene Raised Temperature (PE-RT & PE4710).

Crestwood Midstream Partners LP: Gondor Salt Water Disposal Facility, McKenzie County, ND; PPI member company: Victaulic (Easton, PA)

|

Accepting up to 50,000 barrels per day of produced water, the Crestwood Gondor Saltwater Disposal facility features two wells, two separators, two oil storage tanks, and 10 water storage tanks across nearly three acres. The project, which was constructed using both onsite installation and in-shop fabrication, consisted of 12-in. and smaller HDPE pipe.

Selecting HDPE over metallic piping systems allowed Crestwood to complete the Gondor Saltwater Disposal facility on time and within budget. Victaulic assisted with the design and fabrication of the Gondor project, cutting weeks off of the original construction estimate. The HDPE couplings were installed with minimal effort, and onsite assembly required only simple hand tools, without the risk of weather delays. The Victaulic couplings eliminated challenging fitting-to-fitting connections, and vertical and overhead installation was quickly and easily accomplished, according to PPI.

PPI Municipal & Industrial Division Project of the Year

City of Fort Lauderdale’s Redundant Force Main Project, Ft. Lauderdale, FL; PPI member companies: JM Eagle (Los Angeles, CA) and Agru America Inc. (Georgetown, SC)

|

Construction of a new 7.5-mile redundant forced main sewer required two contractors using horizontal directional drilling (HDD) to install the 54-in.-diameter HDPE pipe. Murphy Pipeline Contractors Inc. (Jacksonville, FL) ran from the north while David Mancini and Sons (Pompano Beach, FL) came from the south. Both companies are contractor members of the Municipal Advisory Board, an independent, non-commercial adviser to the Municipal & Industrial Division of the PPI.

The $65-million wastewater transmission line from the G.T. Lohmeyer Wastewater Treatment Plant to the wastewater lift station was completed in February 2021, months before it was expected. The project was undertaken due to the city’s existing 50-year-old force main, which has experienced frequent breaks during the past several years. It will enable the city to repair the existing force main.

PPI Drainage Division Project of the Year

Project Living Hope Soccer Complex — Camp Marie, Haiti; PPI member company: Pacific Corrugated Pipe Co. (Hubbard, OR)

|

Project Living Hope, a charitable organization, has a vision to create a social center in rural Haiti supporting underprivileged youth in the area. This includes creating a massive sports facility with soccer fields, a housing complex, vocational center, and community hall. After the drainage requirements were identified for the soccer field, it was determined that the low material and installation costs associated with corrugated high-density polyethylene (HDPE) pipe provided the best solution compared to other piping alternatives. It allowed Project Living Hope to complete the soccer field drainage improvements in its entirety, rather than in phases.

Some 1,500 linear feet of Pacific Corrugated HDPE pipe was used in diameters ranging from 6 to 36 in. Without this drainage system, the fields of Camp Marie would have standing water following storms that would take a week of clear weather to dry. Now, rainwater is effectively diverted, leaving the soccer fields clear and available for daily use.

PPI Power & Communications Division Project of the Year

Pacific Gas & Electric — Napa Valley Balloons Installation (Napa, CA); PPI member company: Southwire Co., (Carrollton, GA)

|

The Napa Hot Air Balloon Company wanted to bury existing overhead conductors underground at the launch location of its balloons for safety reasons. To address the customer’s concerns, Pacific Gas and Electric (PG&E) turned to cable-in-conduit (CIC). The goal was to get the trench dug, CIC installed, and filled again with little traffic interruption for a nearby winery. The use of 13,000 feet of Southwire CIC by PG&E for this unique need was an overwhelming success, notes PPI. In addition to time and cost savings, PG&E now has a permanent raceway available in case a need arises to replace or upgrade the cables. PG&E is now considering CIC as a solution for future grid hardening, safety, and fire mitigation projects.

PPI also announced the members of the year, one for each division. They are:

PPI Building & Construction Division Member of the Year: Rick Stock, Uponor Inc. (Apple Valley, MN)

PPI Drainage Division Member of the Year: Joe Babcanec, P.E. Advanced Drainage Systems, Inc. (Hilliard, OH)

PPI Energy Piping Systems Division Member of the Year: Chris Ampfer, WL Plastics, (Ft. Worth, TX)

PPI Municipal & Industrial Division Member of the Year: Barb Donaldson, WL Plastics (Ft. Worth, TX)

PPI Power & Communications Division Member of the Year: Randy Kummer, Southwire Co. (Carrollton, GA)

Congratulations to one and all!

About the Author(s)

You May Also Like