Die is suited for pipes with outer diameters ranging from 2 to 15 inches.

April 19, 2023

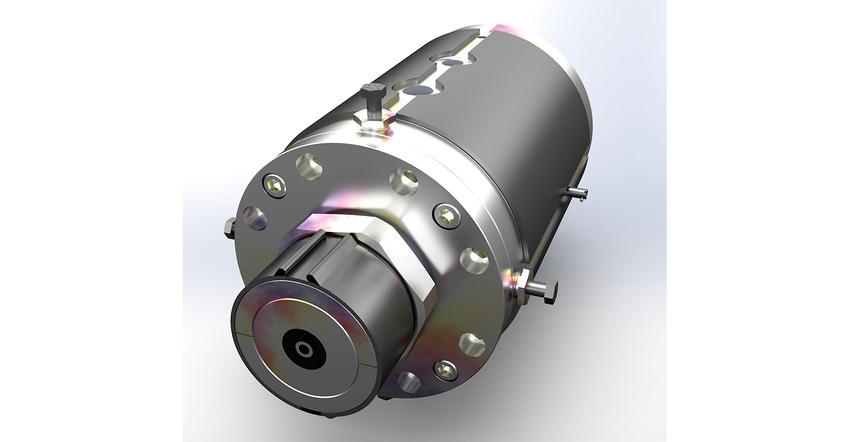

The Spiderless Pipe Die, now available from Guill Tool & Engineering, reportedly reduces the cost of materials compared with conventional basket dies for pipe extrusions.

The global market for pipes used in irrigation and sewage systems as well as industrial applications is expected to grow in the years ahead. Demand for pipes is driven by the increasing need for water and wastewater infrastructure, as well as the growth of industrialization and urbanization. These factors are expected to drive demand for pipes in emerging economies such as China, India, and Brazil, as well as in developed markets including the United States and Europe, according to Guill.

Suited for the production of large-diameter pipes, the die is capable of providing a finished extrusion in outer diameters ranging from 2 to 15 inches. It’s available in 4140 steel or heat-treated stainless steel.

What differentiates the Spiderless Pipe Die design from a basket die is a focus on precision tooling gained from decades of experience in medical tubing, flow analysis, and Guill’s ISO 9001 and AS9100 (aerospace) quality systems. Savings in material costs are also a key factor, said Guill.

The cost of the polymer can account for between 50% and 70% of the total cost of producing the pipes. The cost of other materials such as additives, fillers and reinforcements, as well as the cost of energy, labor, equipment, and overhead also contribute to the total production cost.

Raw polymer cost can be affected by market fluctuations in the price of oil. Additionally, it can also be influenced by supply and demand factors and global trade dynamics, said Guill.

Guill added that its Spiderless Pipe Die is now available to meet the needs of its customers as they consider all the factors needed to remain competitive in pipe production. This product was entirely conceived, designed, engineered, manufactured, and tested at the Guill factory in West Warwick, RI.

About the Author(s)

You May Also Like