United Arab Emirates-based Union Pipes Industry (Abu Dhabi) has purchased equipment from Bauku (Wiehl, Germany) for the manufacture of 3m-diameter polypropylene spiral wound pipes for the Ruwais Refinery Expansion-2 Project of the Abu Dhabi Oil Refining Company (Takreer). The pipes are to be installed for sea water intake and outfall application at Ruwais.

January 11, 2011

United Arab Emirates-based Union Pipes Industry (Abu Dhabi) has purchased equipment from Bauku (Wiehl, Germany) for the manufacture of 3m-diameter polypropylene spiral wound pipes for the Ruwais Refinery Expansion-2 Project of the Abu Dhabi Oil Refining Company (Takreer). The pipes are to be installed for sea water intake and outfall application at Ruwais.

|

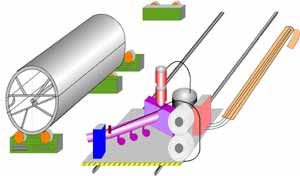

Spiral wound pipe extrusion line installed in Abu Dhabi. |

This will be the first pipeline of its kind to be produced in the region. It will utilize high-stiffness PP High Modulus (HM) pipe grades such as BorECOBA212E from Borouge (Singapore), which are now produced locally at the company's new Ruwais PP production asset.

In the past, Union Pipes extruded a total of 25 km of 1600-mm diameter PE100 pipes to bring sea water to cool the newly expanded Borouge plant at Ruwais. The complete pipeline was butt-welded to ensure leak-free joints that are as strong as the pipe itself, greatly increasing the durability of the system. These HDPE pressure pipes are tough, easy to install, and extremely tolerant to any installation damage that can arise, unlike the glass-fiber pipes used in previous industrial cooling water lines.

Many other large-diameter HDPE pipe projects have followed for both utility and industrial applications, which have ultimately led to even larger diameter extruders being installed in the Middle East region. This has translated to a rapid increase in demand for HDPE, which will be met by the recent capacity expansion in Abu Dhabi.

In Abu Dhabi, Borouge has increased the production capacity of its plant to 2 million tonnes of polyolefins per year and in one of the world's major petrochemical projects, it is expanding its manufacturing capacity to 4.5 million tonnes per year by mid-2014. —[email protected]

About the Author(s)

You May Also Like