Anaheim in Southern California famously is home to the happiest place on Earth—Disneyland, as if that needed to be said—all year round for families.

January 25, 2016

Anaheim in Southern California famously is home to the happiest place on Earth—Disneyland, as if that needed to be said—all year round for families. For three days in February, the medical manufacturing community will share the happiness, and engage in its own form of imagineering, as MD&M West, the largest medical manufacturing trade show and conference in North America, co-located with PLASTEC West, returns to the Anaheim Convention Center on Feb. 9 to 11.

Thousands of exhibitors catering to the medical technology and advanced manufacturing sectors will fill the show floor, while dozens of industry experts, academics and researchers will provide insights on everything from meeting the challenges of medical molding to the future of nano robotics at conference sessions.

Here are five reasons why you might get happy at MD&M West and PLASTEC West. Many more felicitous discoveries await at the Anaheim Convention Center next month.

I, nanobot

It may seem like science fiction, but the notion of nanoscale robots patrolling arteries looking for the first signs of a disease or delivering medication to the precise spot where it is needed is no flight of sci-fi fantasy. Dr. Kwanoh Kim, a Postdoctoral Fellow at the University of Texas at Austin's Cockrell School of Engineering, will discuss this emerging technology during a conference session at MD&M West.

Kim will present a case study, Nanorobots: A Bottoms-Up Approach, that details how minuscule robots can identify problem cells and provide targeted treatment inside a patient's body. His presentation is part of a full-day conference session on Feb. 9 devoted to new product development and next-gen applications.

|

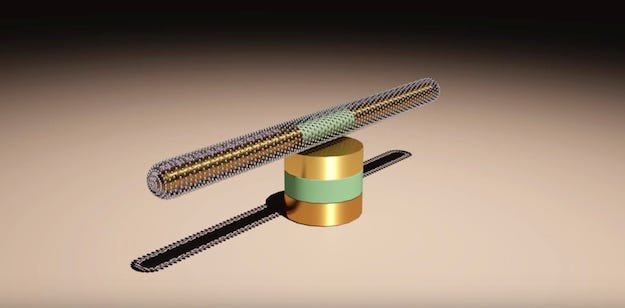

Researchers at the Cockrell School of Engineering have built the smallest, fastest and longest running synthetic nano motor to date. |

Kim has participated in groundbreaking work on nano motors at Cockrell, where a team of researchers recently built the smallest, fastest and longest-running tiny synthetic motor to date. The ultra-high-speed device can convert electrical energy into mechanical motion on a scale 500 times smaller than a grain of salt. These motors one day could move miniature machines through the body to administer insulin or target and treat cancer cells without harming their healthy counterparts.

Molding perfection

Just ask any contract injection molders serving the medtech industry, and they will tell you that OEMs are demanding greater precision and performance from plastic parts and assemblies with increasingly complex geometries. Making precision molded parts for medical applications is critical to a company's success, and John Bozzelli, a consultant at chemicals and plastics distribution company Nexeo Solutions (The Woodlands, TX), will share some advice with MD&M West and PLASTEC West attendees on how to be on the winning side of that equation.

Bozzelli will make several presentations at the Tech Theater discussing proper documentation and tracking of molding processes and the virtue of having one setup sheet per mold rather than for each machine. Check out the full Tech Theater program on the MD&M website.

Elastomers on steroids

New platinum-cured silicone elastomers developed by NuSil (Carpinteria, CA) feature tensile strength that is up to 50% greater than existing silicone elastomers, opening up new possibilities for medical device designers. The company will showcase its line of High Strength Silicones at MD&M West in booth 2327.

The new platinum-cure silicone elastomers provide device and component manufacturers with a super strong, low durometer, high elongation material without compromising hysteresis or tensile set, says NuSil. In particular, the company believes the materials will enable the production of thinner, stronger and more resilient catheter balloons.

The new platinum-cure silicone elastomers provide device and component manufacturers with a super strong, low durometer, high elongation material without compromising hysteresis or tensile set, says NuSil. In particular, the company believes the materials will enable the production of thinner, stronger and more resilient catheter balloons.

The High Strength Silicones also bridge the gap in strength that has historically prevented manufacturers from upgrading to silicone from latex in high-use devices such as mechanical pumps. NuSil says that this new technology platform provides manufacturers with a super strong tubing alternative that has all of the advantages of silicone—durability, translucency and biocompatibility—without the risk of causing latex-related allergies.

But latex replacement is one of many medtech applications for this material, Scott Mraz, Chief Commercial Officer, told PlasticsToday. "Silicone is the preferred raw material in the medical device industry because of its biocompatibility. Our new high-strength elastomer opens up design possibilities that, until now, were not open to silicone because of material constraints. The applications are broad ranging from implants to consumable applications and from small components to large volume applications, anywhere high purity medical-grade silicones can solve customers' design challenges," said Mraz.

NuSil has long-standing partnerships with the world's leading medical device companies, added Mraz, and, as such, it is privy to their design challenges and search for materials with a unique mix of properties that will enable next-generation devices. "Our close supportive relationships with our customers led to this innovation," he told PlasticsToday.

How PolyOne is helping to halt healthcare-associated infections

To combat healthcare-associated infections (HAIs), which affect an estimated 700,000 patients annually, according to the Centers for Disease Control, hospitals have begun using extremely powerful disinfectants to clean reusable medical devices. As a result, materials suppliers have been challenged to formulate plastics that can withstand these harsh chemicals. PolyOne (Avon Lake, OH) is showcasing two new medical-grade thermoplastic elastomers (TPEs) at booth 848 that combine enhanced resistance to commonly used antiseptic cleaners with bonding properties to plastics with improved chemical resistance.

The new Versaflex HC TPEs suited for overmolding onto device housings resist delamination, cracking and loss of resilience from repeated exposure to all antiseptics. Customers have reported that devices made with Versaflex HC TPEs successfully passed 10,000 antiseptic wipe testings. Further, these grades are compatible with PolyOne's USP Class VI-compliant colors for healthcare applications, which resist fading from repeated antiseptic use.

|

The pictured medical device housing incorporates Versaflex HC TPE bumpers from PolyOne overmolded on a rigid susbtrate. |

Available in two Shore A hardness levels, the TPE materials can also be customized to achieve desired haptic qualities, according to PolyOne.

The company is also looking forward to introducing MD&M West attendees to its new website, www.polyone.com, which consolidates the company's global portfolio from 12 legacy websites into one, user-friendly portal. Users can now find information on PolyOne's portfolio of thermoplastic elastomers, plasticizers, engineered materials, colorants, additives and related products in one location. The site also includes enriched career and investor information centers, along with an idea center encompassing case studies, webinars, and insights that links to a searchable resource database filled with white papers, expert articles, videos and literature.

Thoughts from a restless genius

One of three keynote speakers at MD&M West, Ray Kurzweil, who has been described as "the restless genius" by the Wall Street Journal and "the ultimate thinking machine" by Forbes magazine, will discuss how the democratization of innovation is transforming, among many other sectors, medical technology.

Health and medicine is now an information technology, with the collection of the human genome, the means of changing genes in a mature individual, and the ability to design interventions on computers and to test them on biological simulators, notes the man who has been named the "rightful heir to Thomas Edison" and is widely considered to be one of the world's leading inventors, thinkers and futurists. His list of inventions includes the CCD flatbed scanner, omni-font optical character recognition, print-to-speech reading machine for the blind and text-to-speech synthesizer.

Kurzweil is scheduled to speak on Feb. 10. The two other keynote speakers at MD&M West are Dave Zaboski, a master animation artist who has worked his magic at Disney, Sony and Warner Bros., explaining how a thought becomes a thing, and Dominique Courbin and Stephanie Valderrama of Limbitless Solutions, a non-profit organization that uses 3D printing to advance personalized bionics and solutions for disabilities.

The keynote speeches are open to all attendees and are held from 9 to 9:45 AM in room 213 B/C/D on the second floor of the Anaheim Convention Center.

There's still time to register to attend the co-located MD&M West and PLASTEC West events coming to Anaheim, CA, from Feb. 9 to 11, 2016.

About the Author(s)

You May Also Like