Foster Polymer Distribution, a business unit of Foster Corp. (Putnam, CT) specializing in the distribution of medical polymers and additives, has partnered with Mitsubishi Gas Chemical (New York) to distribute MX nylon to the North American medical market. MX nylon, a meta-xylene diamine polyamide, offers mechanical and barrier properties suitable for molded components and devices, and for use in medical packaging applications.

April 17, 2015

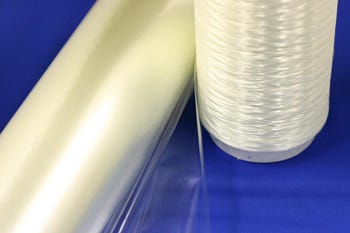

Foster Polymer Distribution, a business unit of Foster Corp. (Putnam, CT) specializing in the distribution of medical polymers and additives, has partnered with Mitsubishi Gas Chemical (New York) to distribute MX nylon to the North American medical market. MX nylon, a meta-xylene diamine polyamide, offers mechanical and barrier properties suitable for molded components and devices, and for use in medical packaging applications.

Metal replacement is one area where the material has tremendous potential. Polymer components are frequently preferred over metal in medical equipment since they do not interfere with magnetic resonance imaging (MRI), computerized axial tomography (CAT), fluoroscopy and x-ray imaging. MX nylon is a high-strength metal replacement material with a flexural modulus 50% greater than traditional polyamide 6/6 and 15% greater than polyetheretherketone (PEEK). It also has a cost advantage, since it is priced 25% less than PEEK, according to Foster Corp., making MX nylon an economical option for high-strength components that must be radiolucent.

Metal replacement is one area where the material has tremendous potential. Polymer components are frequently preferred over metal in medical equipment since they do not interfere with magnetic resonance imaging (MRI), computerized axial tomography (CAT), fluoroscopy and x-ray imaging. MX nylon is a high-strength metal replacement material with a flexural modulus 50% greater than traditional polyamide 6/6 and 15% greater than polyetheretherketone (PEEK). It also has a cost advantage, since it is priced 25% less than PEEK, according to Foster Corp., making MX nylon an economical option for high-strength components that must be radiolucent.

MX nylon also offers superior gas barrier properties against oxygen and carbon dioxide compared to all commercially available polyamides, as well as ethylene-vinyl alcohol (EVOH) copolymers, acrylonitrile (PAN) copolymers, and polyvinylidene chloride (PVDC) copolymers, says the company.

Heat stability and a wide processing window allows co-extrusion and co-injection molding of the polyamide with other polymers, such as polyethylene terephthalate (PET), polypropylene (PP) or polyethylene (PE) for multi-layer medical packaging or containment systems that require low oxygen permeation. MX nylon is also suitable for applications that must withstand sterilization by gamma, E-beam, ethylene oxide and retort methods.

"MX nylon has been very successful in a wide variety of applications and industries. We are excited to partner with Mitsubishi to promote the benefits of this unique material in medical devices and equipment," said Brittany Palmer, Foster Distribution Business Manager. "MX nylon grades are currently available for injection molding and extrusion."

About the Author(s)

You May Also Like