No one is denying that 2009 was a tough year, but in spite of that, hot runner suppliers didn’t bury their heads in the sand. They kept an eye on emerging markets and new applications, and developed new products designed to meet new molding technologies.

July 7, 2010

No one is denying that 2009 was a tough year, but in spite of that, hot runner suppliers didn’t bury their heads in the sand. They kept an eye on emerging markets and new applications, and developed new products designed to meet new molding technologies.

Hot runner systems seem to be hottest in specific markets and in specific geographic regions. Global demand is picking up overall, and particularly in China as manufacturing recovery started early there. As more tooling purchasers understand the value of hot runner systems in the molding process, these systems will continue to gain in value, and thus price will become less of a factor.

|

Systems to accommodate a range of molds will continue to evolve as demand for smaller molds, micromolding, and high-cavitation molds for extremely small parts increases. Molders will continually seek greater productivity and efficiency, and reduced material scrap, all of which are benefits of hot runner systems. Will OEMs be willing to pay a higher cost for these benefits? In many cases, yes, but these systems will remain a tough sell for moldmakers, which means the hot runner manufacturers must take on the job of selling the value of their products to the mold purchasers.

Q: What event or condition is having the biggest effect on your sector of the plastics industry in 2010, and which one do you think will be the most important in 2011?

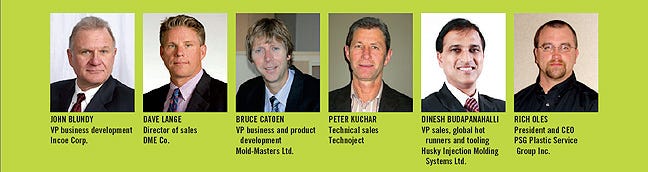

Blundy: Hot runners’ productivity opportunities continue to be a part of many injection molding markets, and there are some applications where the only method for successful molding is with the use of hot runners. We are providing systems in a variety of markets, many of which are doing well as we continue to climb out of the recession. Automotive and the electronics markets are among those improving currently.

Lange: We are hearing two major trends from our customers. First, raw material prices are going up. With the increase in the price of resin, customers are more inclined to reduce scrap and waste. Hot runner systems are excellent ways to do that. Secondly, volumes are starting to increase as the economy improves. As that happens, it becomes easier for processors to justify the cost of a hot runner system by amortizing the tooling cost over a larger volume of parts being produced.

Both of these will be major factors in the industry in 2011. We want to see the economy continue to flourish and consumer confidence continue to improve. We are seeing a direct correlation between the increase in volumes and our hot runner business.

Catoen: It is apparent to Mold-Masters that the global economic recovery and the stability of the banking industry have a direct impact on the sales of hot runner systems. As the financial institutions stabilize and in turn free up the availability of cash, this positively affects the growth potential of all capital equipment in the injection molding industry. We are also seeing pent-up demand for tooling in the marketplace. This is probably a bit of a bubble as customers sat on their wallets in 2009, and must spend in 2010 to meet increasing demand and to replace worn tooling.

Kuchar: We were surprised at the number of new leads we got at both the Plastec West and the PDx/Amerimold trade shows. For us the most important event will be Plast-ex.

Budapanahalli: The primary drivers influencing hot runner growth come from a variety of factors. The emerging BRIC (Brazil, Russia, India, and China) countries will have a growing need for hot runners in the consumer electronics, packaging, and automotive markets. More mature markets like Europe and North America will require hot runner technology supporting high-performance and complex packaging, precision medical applications, as well as part light-weighting initiatives.

To satisfy these trends, suppliers must be able to develop products that can handle a wide range of weights, sizes, and dimensions. This is achieved by constantly developing and testing hot runners, controllers, and nozzles against the most challenging standards and applications.

Oles: The increase we’re seeing in consumer spending is having the biggest impact on our business because we serve so many markets. The molders we do business with are much busier than they were in 2009, and many new projects are going into production, which brings us more opportunities to sell product than we had 12 months ago. The weakening of the euro is also having an effect. That helps my business here in North America, but I should add that it’s not helping my corporate parent, which is based in Germany. For 2011, the continuation of growth in consumer spending, the strengthening of the U.S. economy, and bringing more manufacturing back to North America are the big things we’re looking at that will determine how 2011 will turn out.

Q: What was your company’s top technology development in 2009? What will it be this year? Is there a technology in your sector that processors are overlooking?

Blundy: We have been providing improved melt management solutions through our collaboration with Beaumont Technologies that benefit processors in superior part quality as well as production advantages.

Lange: DME’s top advancement in hot runner technology in 2009 was the advanced micro-nozzle for processing close center-to-center small part applications, such as medical polycarbonate. One of the major trends in the industry is micromolding. This product has a smaller outer-diameter physical dimension and a smaller inner-diameter flow channel. The spacing between one nozzle and the next is closer, which allows for molding smaller parts.

We are continuing to explore miniaturization of some of our products, especially for small-part medical applications. Historically, those footprints have been a little bit larger because of the restraints of the nozzle diameter. For the micro-nozzle, we had to re-examine the nozzle and then explore heater technology that would provide optimal heat distribution.

Another major innovation we introduced is the PETS electric valve gate line this year, primarily for high-precision, stringent cleanroom environments. Some of the key features of this product include variable pin speed, powerful closing force, and consistent repeatability.

Catoen: The development of a hot tip and valve-gate solution engineered specifically for the cap and closure market. Our Sprint product line addresses the demand for a hot runner system that can run at sub-3-second cycles. Also, the development of our Femto-lite VG allows for valve gating into very small (12-mm) bores in the gate without compromising steel integrity.

Kuchar: The innovation of the two-piece Star-Line Crown nozzle has been our top development in 2009. The technology that we feel processors are overlooking is the tandem technology, as they can double productivity and save 40% of the production costs using this technology.

Budapanahalli: In 2009, we launched our Altanium Neo2 temperature controller for two to 24 zones. Altanium Neo2 is significant because with controllers less than 24 zones, molders are often limited to a lower-quality interface. Altanium Neo2 offers a more sophisticated design and features that are normally only associated with high-end temperature controllers, yet it does all that at an affordable price. In 2010, we are expanding Altanium Neo2 up to 48 zones.

In 2009, we saw our UltraSync technology experience great market acceptance, especially in medical applications. Ideal for tight-pitch applications, UltraSync technology offers part-to-part consistency through precise simultaneous gate closing and can be used in cleanroom applications. This means more precise parts produced time after time.

Oles: 2009 was, for the most part, a year of refinements in our technology. Customers were looking for significant cost reductions in a tough market. So we spent a lot of time addressing their needs. However, we did announce our new ProfiTemp hot runner controller at last year’s Fakuma [trade show], and it will be available this year. We think it’s a robust design with a significant advance in performance and features, and it’s a true global product. As important, the price point will be lower than high-end models in years past.

Q: Are there particular end markets that are hot now or will be soon for your customers?

Blundy: Hot runner systems enjoy a wide variety of applications and markets. Our forecast is for continued growth domestically in the medical market. As the boomer population moves toward retirement age, the need for medical devices will continue to grow.

Lange: Medical and packaging are especially hot industries right now. That is where we are doing a large portion of our business and seeing significant success.

Automotive took a big hit when the economy slowed. It’s starting to come back around, but slowly. In the heyday, there were about 17 million cars being produced in the North American market. The recession cut that number almost in half, with all the plastic parts that went into vehicles taking a hit as a result. More cars are being produced as things recover, but it’s definitely taking its time.

Catoen: The demand for hot runners in Asia has continued to outpace all other geographic areas. There is, however, a trend towards onshoring in North America and Europe. Jobs that went offshore for reduced labor and capital costs are returning to the U.S. and Europe when there is a concern for quality and reliability. OEMs and molders have realized that there is a cost to doing business overseas and they are now factoring this into the overall lifecycle cost of a molded part.

The medical market was always important and it keeps growing at a fast pace. Automotive customers are picking up on their parts production. Packaging is extremely important for us and we addressed the market demands with our new high-speed closure solution, Sprint.

Kuchar: We are getting a lot of inquiries regarding close-pitch applications from the medical molders.

Budapanahalli: With the growth of emerging markets also comes the need to be able to responsively serve and support these customers at the local level, in their language and time zone. Suppliers who will successfully meet this need are those who maintain, and continue to develop, a global manufacturing footprint with a wide range of sales and service support to effectively meet the local needs of customers regardless of their size or geographic location. Many new entrants into the emerging markets are also looking for experienced suppliers who have the depth of knowledge to support the development of their operations. These shifts have made it important for manufacturers to partner with industry leaders who have the capabilities and expertise to fully support projects from part concept through to completion.

Oles: PET preforms have been, and continue to be, a hot market for everybody. Here in North America we focus on a lot of specialty applications, technical resins, and filled materials, and we see high demand for color change applications.

Q: Which breakthroughs or major trends in your segment of the plastics business should processors watch closely?

Blundy: The environment is a major topic in our industry, both from the standpoint of opportunity and regulation. Much effort is being put into developing environmentally friendly materials. We are carefully monitoring these materials so that we can be aware of any special processing requirements with regard to our equipment in order to provide our customers with the results they expect.

Lange: There are two major trends in our segment (hot runners) of the industry right now: multimaterial applications (two-shot molding) and smaller footprints in the area of stack molds.

A lot of processors are molding particular parts with two different materials in the same mold, as opposed to doing it post-assembly. Doing it inside a single mold creates an integral part instead of two separate molding operations.

Another big trend is using a smaller footprint in the area of stack molds to increase productivity. This allows processors to get double the volume out of a mold on the same press, and keeps them from having to go to a larger press because of a larger projected surface area.

The larger the projected injection molding surface, the larger the tonnage of machine is needed. By molding in the same projected area and getting double the cavitation, molders increase their volume. Smaller stack molds address the productivity improvements molders are looking for, while allowing smaller mold configurations.

Catoen: Multimaterial. In the recent downturn, this market stayed very robust and there are many new applications that require multimaterial or coinjection technology.

Kuchar: We think more people will be interested in tandem molding simply because of the benefits of increasing productivity while decreasing the production costs.

Budapanahalli: Lightweighting—a number of factors, including rising resin and transportation costs, growing environmental awareness, and consumer demand, are all factors coming together to create an ever-increasing need for lighter-weight packaging. As a result, manufacturers are looking for suppliers who can provide not only the products, but also the services and expertise, to help them produce increasingly lightweight, yet still high-functioning parts.

Increased precision—especially important in the medical market. Molders require technology that can handle increasingly tight-pitch applications. Parts for medical applications are also typically smaller, lightweight, and require high levels of precision.

Shorter lead times—intense competition has significantly reduced our customers’ product launch timelines. This is magnified by the industry’s increasingly global outlook. With growing competition among companies comes a global demand for more flexible, economical hot runner and controller systems that can be delivered with faster lead times. We are finding that many of our customers are looking for the support to bring products to market faster, while still achieving the highest levels of productivity at the lowest part cost. We continue to satisfy this need by offering global tooling standardization and management of complete, system-level solutions.

Oles: There are a lot of new press technologies, and they’re allowing faster-moving presses with a higher accuracy of parallelism, and more accurate real-time reporting back of monitored clamp tonnage and tiebar strength, along with shot pressure and other technical measurements. We’ll all be looking at longer tool life, longer intervals between maintenance, and we’ll witness a rise in the use of aluminum tooling for production applications.

Q: What is your prediction for your industry segment’s growth in 2011? Better than 2010?

Blundy: On a global demand basis, we see enormous opportunity in China for automobile components. It is not only a requirement to provide quality hot runner systems as key to being a preferred supplier, but the ability to supply technical design support in the early stages of development and mold installation are critical as well. Global capabilities are a must.

Lange: Our first quarter in 2010 was up significantly at DME. We anticipate that growth will continue, both over the remainder of this year and into 2011. In the first four months of this year, we’ve seen a large increase in the number of molds we’ve sold and the associated components that are installed in them. We suspect this is mostly due to market recovery, but we have had some new product introductions that have contributed as well.

Many of our industry colleagues are also optimistic. We attended the Injection Molding Magazine/Modern Plastics Worldwide executive roundtable in Chicago in April and got a feel for trends and tone of the industry. The general consensus is that things are on an upswing for the entire industry, and it looks like it will continue.

Catoen: The hot runner market growth in 2010 over last year should be strong at 5%-7% globally.

Kuchar: We feel that by the end of 2010, we will be back to the same level of sales as 2008, and could see a 10%-15% increase in 2011.

Budapanahalli: We are finding that our customers, both existing and new, share an enthusiasm about the future and see significant opportunities for growth. Our goal is to provide our customers with the products and services to meet their needs and to help them be more competitive.

Oles: We’re forecasting significant year-over-year growth in 2011 vs. 2010. At this point, we still forecast market growth in 2011, and we’re prepared to add capacity as markets continue their recovery. However, let’s face it—with the European economy in its present state, a double-dip recession here in North America is certainly a possibility. That means that we’re continuing to staff our operations as lean as we can. —Clare Goldsberry

About the Author(s)

You May Also Like