When it comes to color, getting it right can be a challenge. Adding color will always affect the polymer being processed, although the way in which it does so will vary from plastic to plastic, and even from color to color. Converters are faced with choices such as using higher doses of weaker masterbatches, which facilitates an even dispersion throughout, or small quantities of a stronger masterbatch, which can offer cost advantages. Wall thickness, color, transparency, and application are all factors that affect the choice of a masterbatch.

August 28, 2014

When it comes to color, getting it right can be a challenge. Adding color will always affect the polymer being processed, although the way in which it does so will vary from plastic to plastic, and even from color to color. Converters are faced with choices such as using higher doses of weaker masterbatches, which facilitates an even dispersion throughout, or small quantities of a stronger masterbatch, which can offer cost advantages. Wall thickness, color, transparency, and application are all factors that affect the choice of a masterbatch.

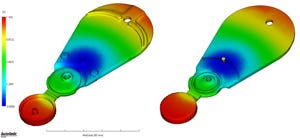

Granula, a major masterbatch producer based in Switzerland and Germany, sought a way to systematize these effects. The company is offering a service that is aimed at helping customers oversee their masterbatch decisions at an early stage, before their product goes into series production. Together with a group of mechanical engineering students at Reutlingen University, the company has come up with a test specimen that has been designed specifically to enable masterbatch customers to analyze a number of important properties of colored plastics and plastic part design requirements in advance. Based on this test specimen, various constructional and design aspects can be tested in order to determine whether a color performance is delivered that is compliant with the specification of the relevant plastic part.

Granula, a major masterbatch producer based in Switzerland and Germany, sought a way to systematize these effects. The company is offering a service that is aimed at helping customers oversee their masterbatch decisions at an early stage, before their product goes into series production. Together with a group of mechanical engineering students at Reutlingen University, the company has come up with a test specimen that has been designed specifically to enable masterbatch customers to analyze a number of important properties of colored plastics and plastic part design requirements in advance. Based on this test specimen, various constructional and design aspects can be tested in order to determine whether a color performance is delivered that is compliant with the specification of the relevant plastic part.

The students, a graduate class of 17 students overseen by Professor Steffen Ritter, were assigned the task of developing the new test specimen for color masterbatches. The main application was to be packaging, and polyolefins were the main polymers. This implied that packaging features such as living hinges, different wall thicknesses, and surface structures needed to be integrated into the model.

A plain area was also required to be included in order to measure the colors for qualification of masterbatches.

The project started in the fall of 2013. Two teams were formed, each responsible for part design, to compete in the creation of the most innovative component suited to Granula's purposes. The end result, which combined the best of both teams, boasted many packaging-related features, including a superb design solution for integration of the hinges. The test specimen has a distinctive appearance, enhancing its recognition value.

Another group of students developed the injection mold, which then was built by an external toolmaker. Followed by initial sampling and optimization phases, the first production trials have commenced at the university's plastics learning factory.

An energy-efficient Boy 25E injection-molding machine will demonstrate production of the new test specimen at the upcoming Fakuma trade show, which runs from Oct. 14 to 18 in Friedrichshafen, Germany. Granula can be found in Hall B4, Booth 4007.

About the Author(s)

You May Also Like