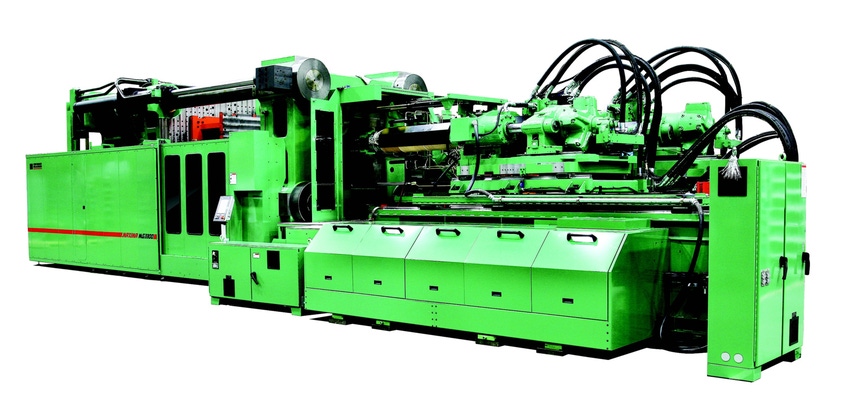

Batavia, OH—Plastics processing equipment maker Milacron and Bemis Manufacturing Company, one of the largest U.S. injection molding firms, have a long history of joint innovation when it comes to co-injection technology, and the firms added another chapter this week.Their latest collaboration has resulted in the industry's largest Servo Hybrid co-injection machine-the 1500-ton Maxima Servo, which ran at Milacron's recent open house, April 24-25.

April 26, 2013

According to Milacron and Bemis, the companies created what they call the industry's most versatile multi-component Servo machine, with seven unique process capabilities. "After seeing our Maxima Servo platform at NPE 2012, Bemis recognized the value of combining co-injection and servo technology," said Jim Moore, VP Automotive Business at Milacron. "Bemis's deep-rooted commitment to zero waste and energy conservation aligns perfectly with the Maxima's efficient servo motor technology, which uses less than half the energy of a comparable 1500-ton hydraulic press."

Co-injection (or encapsulation) can improve environmental sustainability and reduce costs by making it possible to include recycled or reground resin; technical grades of resin with material properties to improve part characteristics such as sound deadening or cold weather impact strength; or more economical material in the core with another material molded over the core material for aesthetics.

Gary Vande Berg, vice president engineering for Bemis Manufacturing, was present at the Milacron open house to answer questions about this latest technology.

Co-injection from 1992 to 2013

"Each machine gets better," he told PlasticsToday. "From the first one we developed with Milacron in 1994 to this one with the new servo pump system, which offers greater efficiency and a platform for sustainability - not just environmental sustainability but business sustainability. You can do all you want for environmental sustainability, but if you have no business sustainability, what good does it do?"

Vande Berg noted that they have the "twin" to this machine running at the Bemis facility in Sheboygan Falls, WI, that is "sold out." The company currently has 32 co-injection machines. An 1100-ton is currently being built at Milacron's Batavia, OH, facility.

"We may have been a bit far ahead of the curve with this technology when we started out," he said. "In 1992, we looked a lot of technologies before we came up with this." Bemis obtained the original patents to the co-injection technology and licensed it to Milacron, asking them, "Can you build it?" The rest is a long and successful history between the two companies.

"We're seeing the most interest in this technology than we've ever seen," stated Vande Berg. "This technology may have come of age."

About the Author(s)

You May Also Like