It's been a long road to bring mold manufacturers to the point where they use 3D printing (additive manufacturing) to bring real value to their business, but it's finally taking hold. Hasco (Lüdenscheid, Germany), an innovative moldmaker with a global footprint, and Stratasys Ltd. (Eden Prairie, MN), a global provider of 3D printing and additive manufacturing systems, announced that Hasco has developed a rapid, cost-efficient method of producing low volumes of injection molded prototypes by integrating Stratasys 3D printing with its K3500 quick-change mold system.

October 3, 2015

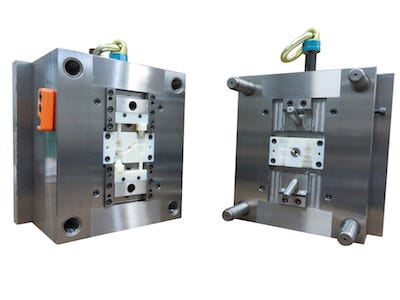

It's been a long road to bring mold manufacturers to the point where they use 3D printing (additive manufacturing) to bring real value to their business, but it's finally taking hold. Hasco (Lüdenscheid, Germany), an innovative moldmaker with a global footprint, and Stratasys Ltd. (Eden Prairie, MN), a global provider of 3D printing and additive manufacturing systems, announced that Hasco has developed a rapid, cost-efficient method of producing low volumes of injection molded prototypes by integrating Stratasys 3D printing with its K3500 quick-change mold system. Using this innovative approach, molders can quickly change between inserts for different products, enabling them to cost-efficiently produce low volumes of injection molded parts for samples, prototypes and small production runs.

Hasco 3D prints the inserts in Stratasys' ultra-tough Digital ABS material using the Objet 500 Connex multi-material 3D production system. With a 3D printed mold insert taking only hours to produce, molders can make design modifications to the product at a fraction of the time and cost of conventional tooling methods.

Hasco 3D prints the inserts in Stratasys' ultra-tough Digital ABS material using the Objet 500 Connex multi-material 3D production system. With a 3D printed mold insert taking only hours to produce, molders can make design modifications to the product at a fraction of the time and cost of conventional tooling methods.

"With time-to-market cycles shorter than ever and production quantities dropping, our customers are now looking for solutions that enable them to deliver prototypes quickly and cost effectively," said Dirk Paulmann, Executive Vice President, Sales and Business Development, at Hasco. "Compared with conventional metal or aluminum inserts, our new approach offers molders the flexibility to quickly produce and switch inserts, making them much more productive and profitable. Combining our longstanding heritage in moldmaking with Stratasys' pioneering expertise in 3D printing injection molds, this best-of-both-worlds technique is the future of prototype and low-volume production."

Hasco told PlasticsToday that since the company has been promoting the value-add advantages of 3D printing of mold inserts, they have experienced quite a bit of interest from U.S. moldmakers. While some are still in the "curiosity" stage, some have viable projects that warrant further research using the Stratasys Digital ABS material. "It requires moldmakers who think outside the box and can see the opportunities," said Hasco. "We can show them just what can be done with 3D printing and product development."

When producing a sealing plug for its industry-standard A8001 clamping fixture, Hasco identified that the walls of the ABS plastic sealing screw would need to be 12-mm thick to seal the large number of threaded holes. Given this geometry, it was clear that the screw could not be produced using a conventional injection molding process. With the level of intricacy enabled by Stratasys Polyjet 3D printing, Hasco redesigned the screw with a reduced wall thickness and subsequently 3D printed a mold insert to the new specifications in order to test the integrity of the design before mass production.

"The speed of the process was incredible," explains Paulmann. "Using our Objet 500 Connex 3D production system, we produced the parts of the cavity that shape the polymer—such as the inserts and slides—in just six hours compared to the 24 hours it previously took. We then worked with prototyping specialists Canto Ing. GmbH, in Lüdenscheid, Germany, to finish the 3D-printed inserts and test the sample mold. We were delighted with the result. The first sealing screws were produced ready for mounting on our clamping unit in a record time of only four days.

"The speed of the process was incredible," explains Paulmann. "Using our Objet 500 Connex 3D production system, we produced the parts of the cavity that shape the polymer—such as the inserts and slides—in just six hours compared to the 24 hours it previously took. We then worked with prototyping specialists Canto Ing. GmbH, in Lüdenscheid, Germany, to finish the 3D-printed inserts and test the sample mold. We were delighted with the result. The first sealing screws were produced ready for mounting on our clamping unit in a record time of only four days.

"Through the use of tried-and-tested standardized Hasco products and Stratasys' state-of-the-art 3D printing, the project has proved that it is possible to implement this innovative rapid-technology application within the injection molding process. For the production of low-volume prototypes in the final product material, the ability to quickly change molds with a 3D-printed cavity offers a rapid, low-cost alternative to conventional methods," says Paulmann.

Nadav Sella, Director, Manufacturing Tools, Vertical Business Unit, Stratasys, concludes: "We're extremely excited about what this collaboration has done to advance the low-volume injection molding process and the resulting manufacturing efficiencies that can be achieved by molders. We view this as an application area with significant potential and will continue to work with partners such as Hasco to further extend the benefits of additive manufacturing into the world of moldmaking and injection molding."

About the Author(s)

You May Also Like