Clean Room Devices, a specialist in tubing assembly equipment based in Westminster, CO, is introducing an Automatic Fitting Inserter that allows high-speed assembly of tapered-barb connectors and tubing made from thermoplastic elastomers (TPEs).

March 5, 2013

Clean Room Devices, a specialist in tubing assembly equipment based in Westminster, CO, is introducing an Automatic Fitting Inserter that allows high-speed assembly of tapered-barb connectors and tubing made from thermoplastic elastomers (TPEs).

The technology development, which advances the potential replacement of polyvinyl chloride in medical applications, was announced at MD&M West in Anaheim, CA last month by Clean Room Devices and Teknor Apex Co. (Pawtucket, RI), which produces Medalist MD-500 TPEs and other plastics.

|

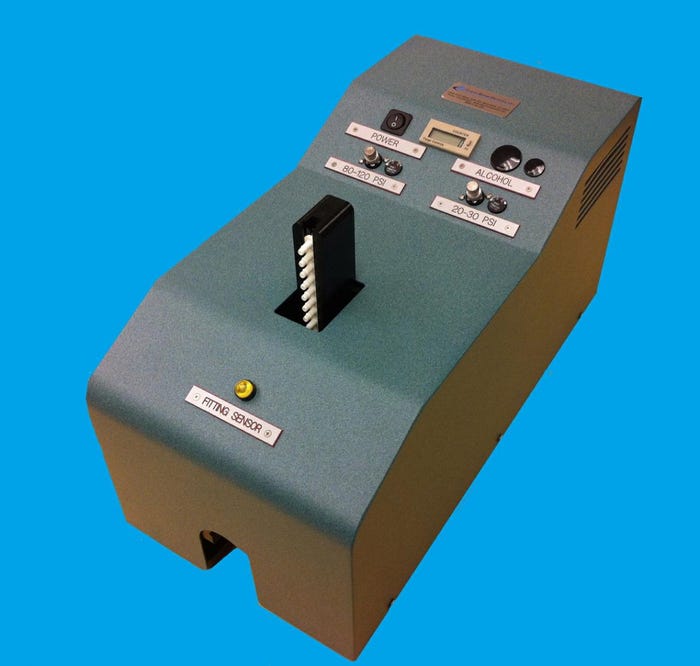

New assembly tool for TPE tubing. (Teknor Apex) |

"Tapered-barb connectors fit into the Medalist TPE tubing with a retention strength that exceeds the 35.6 N (8.0 lbf) level specified by most global OEMs for infusion systems and is greater than levels achieved with either adhesive or solvent bonding," said Richard Faulkner, medical market manager for the Thermoplastic Elastomer Division of Teknor Apex. "The automatic fitting inserter developed by Clean Room Devices enables medical product manufacturers to obtain strong, secure connections even at very high assembly speeds."

The CRD 600 unit cycles at a rate of 2,300 per hour and, with the addition of a feeder bowl, enables an operator to make 1,800 insertions per hour, including time for handling the tubing and inspecting the results, according to Ronald Del Valle, president of Clean Room Devices.

"Because the CRD 600 allows for insertion of over-sized barbs into tubing with a smaller internal diameter, it ensures a stronger fit than solvent bonding," Del Valle said. "A big advantage of our system is that it eliminates the presence of solvent chemicals and odors in the clean room."

Solvent bonding is the standard assembly technique for PVC tubing. Several assembly options are now available for tubing based on Medalist MD-500 TPEs. In addition to the insertion of barbed fittings, these include patent-pending TPE-specific technologies developed by Teknor Apex for solvent bonding and for room-temperature and light-cured adhesive bonding.

Medalist MD-500 compounds are considered a strong competitor to PVC for medical tubing applications because they exhibit comparable clarity and mechanical properties; provide similar clamp resilience and resistance to kinking and necking; have a similar "feel"; and are substantially more flexible and significantly less dense than PVC. At the same time they undergo minimal color shift upon heat aging after exposure to gamma irradiation, the most severe type of sterilization. A typical compound in the series, Medalist MD-575, actually exhibits 70% less heat-aged color shift than a gamma-stabilized PVC compound of comparable hardness.

About the Author(s)

You May Also Like