The new Ford 3.5-L and 3.7-L engine manifold uses a cross-over coolant component made of DuPont Zytel HTN PPA (polyphthalamide) resin instead of brazed metal, shaving one pound to improve fuel economy. Behind the scenes, the running change illustrates the trend toward using high performance thermoplastic where it is essential.

December 11, 2013

The new Ford 3.5-L and 3.7-L engine manifold uses a cross-over coolant component made of DuPont Zytel HTN PPA (polyphthalamide) resin instead of brazed metal, shaving one pound to improve fuel economy. Behind the scenes, the running change illustrates the trend toward using high performance thermoplastic where it is essential.

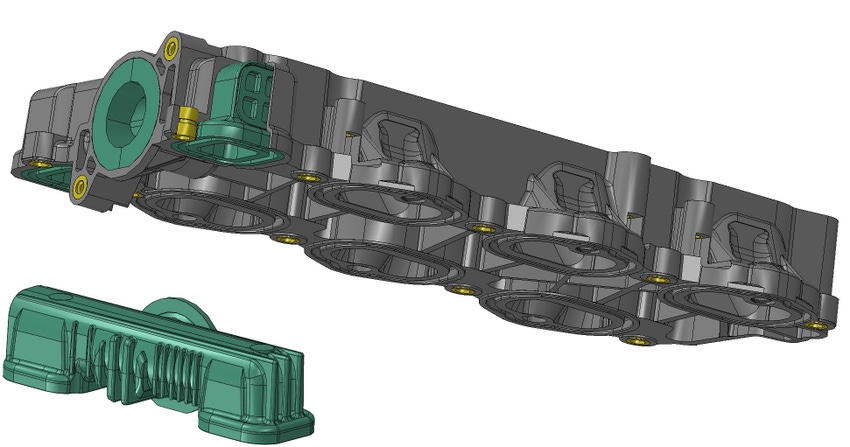

A team from Illinois Tool Works, Inc. (ITW) in Ohio arrived at DuPont's Innovation Center in Troy to brainstorm how to integrate a crossover coolant component into a V6 engine manifold that is made of traditional nylon polymer. The crossover coolant component is a hollow port that allows engine coolant to bypass the manifold as it circulates through the engine. Traditional polyamide 6 polymer doesn't withstand long-term exposure to heat and long-life coolant, so the ITW team was receiving the component made of brazed metal, which was heavy and expensive.

|

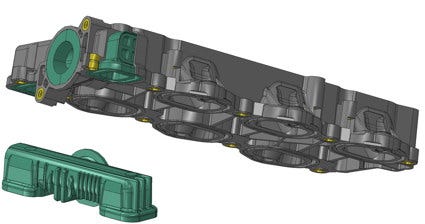

This Ford engine manifold has an overmolded coolant cross-over made with DuPont Zytel HTN PPA and is manufactured by Illinois Tool Works, Inc. (ITW). The team from Ford, ITW and DuPont were named finalists in the Society of Plastics Engineers Most Innovative Use of Plastics Award in the Process/Assembly/Enabling Technology category. |

While DuPont Zytel HTN PPA is frequently used in engine cooling components because it can withstand the long term exposure to heat and long life coolant, the intense pressure of the overmolding process needed to integrate the component into the manifold system was damaging the hollow component.

The cross-functional team approached the challenge from several perspectives related to design, material and processing. Over the following weeks the team modified the material and the design using advanced computer models to inform the prototype. ITW invested in cavity-pressure sensing technology from RJG, Inc. to understand pressures inside the molding cavity. The data was used to pinpoint where design changes could add structure and to control the process so the prototype could scale into production quickly.

"Getting accurate data about pressures and conditions inside the molding cavity significantly improved our ability to evaluate the material, iterate more efficiently on design and shorten the development cycle," said Tyler Terrell, ITW project manager. "This was a really tough challenge and we used every technology we could to get this part into production. The collaboration between the members of this team really made the difference."

"There's a growing trend toward using high-performance materials only where they are needed," said Pat Granowicz, powertrain segment leader, DuPont Automotive Performance Polymers. "This can lead to challenging designs and demand innovative processing solutions. Modelling based on how a material behaves in processing and in use is critical."

In addition to significant weight savings, the running change eliminated several steps in the value chain associated with processing and machining powder-coated metal. For the advances, Ford and the team from ITW and DuPont were named finalists in the Society of Plastics Engineers Most Innovative Use of Plastics Award in the Process/Assembly/Enabling Technology category.

It was one of two 2013 finalists. The other - an acoustic shield mounted on the 2013 Hyundai Elantra and Forte cylinder block - was developed by a team from Hyundai Motor Company, NVH Korea Co., Ltd. and DuPont. The application relies on heat and flame resistant DuPont Nomex brand fiber to withstand the demanding engine environment.

The new integrated coolant crossover debuts on Ford's 3.5L and 3.7L V6 engine that powers the Ford Taurus, Flex, Edge and Explorer.

About the Author(s)

You May Also Like