Sponsored By

News

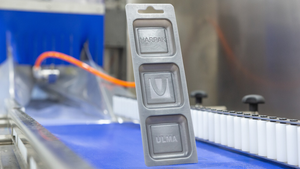

ultrasonic welder

Auxiliaries

Next-gen Ultrasonic Welders Have Plastics FixationNext-gen Ultrasonic Welders Have Plastics Fixation

Rinco Ultrasonics aims to show NPE attendees how they can improve efficiency and productivity with next-gen pneumatically driven ultrasonic welding technology.

Sign up for the PlasticsToday NewsFeed newsletter.