February 1, 2002

Everyone tells me I must have guts starting a business during a downturn," says Ron Ernsberger, president of 20/20 Custom Molded Plastics. "But in fact, we were too far along in our business plan to stop when the economy tanked. Molding machines have to be ordered 12 months in advance, and at the time we ordered, it appeared the economy knew no limits to growth."

Despite the worst downturn in what some experts say is 10, 20, or even (fill in the blank) years, Ernsberger, along with partners David Blosser, David Rupp, Jay Stuck, and Toby Ernsberger (son), persevered at the task of bringing a custom structural foam molding operation to life. Their efforts have not been in vain. The fledgling facility, opened in June of last year and situated amidst a 36-acre field, is comfortably busy and profitable.

|

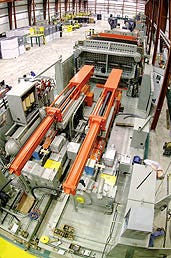

Two 500-ton presses share one side of the plant with a new 1000-ton machine. A 45-ton overhead crane services the entire plant. |

Likely to Succeed

Are there any factors that contributed to this plant's success? For one, the dynamics are different for structural foam than for traditional injection molding. "There aren't that many molders doing it, so there is less competition and market saturation," he says. "There are a lot of good injection molders, probably 60 within a 60-mile radius of us, but perhaps only a dozen custom structural foam molders in the whole country."

Another reason could be experience. Ernsberger has been molding plastics since 1965. He began in compression and injection molding, and then discovered the structural foam process in 1977. He proceeded to spend 22 years modifying two existing structural foam businesses and opening a third, building them into prosperous concerns. This is the first time that he and his partners started from a greenfield site. "I've done this three times before and learned from the experience each time. I believe we've structured this new business for success in just about every way possible. We want it to be the benchmark."

To those who would predict the demise of this process, Ernsberger offers another picture. For one, industry sales have tripled since 1985 on the strength of new applications. For another, he has always found customers for structural foam, and sees the process as advantageous during the current business doldrums. It uses less energy and resin per part, saves on tooling because it requires only aluminum molds rather than tool steel, and reduces production and per-piece costs.

|

|

Long conveyor tables help the large parts molded in this 500-ton press to cool sufficiently before being boxed and shipped. | |

| |

Programmable nozzle controls allow technicians to choose from eight sequences, or to program each nozzle individually. |

SFM Basics

These aren't the only differences between structural foam molding (SFM) and traditional injection molding. SFM is a low-pressure process that incorporates nitrogen gas or another chemical blowing agent that is injected during the melting phase and dissolves in the molten resin. During resin injection, the gas expands to fill the mold with foam, pressing the plastic against the walls of the cavity so that the cells on the surface collapse to form a solid skin.

Part weight reduction can reach 20 percent, and because pressures are lower, sink marks are not an issue. SFM also handles large parts with ease, and imbues stiffness by increasing the thickness of the part's solid walls. Typical SFM products include returnable shipping pallets, carts, buckets, containers, window shutters, cabinets for IT equipment, in-ground filtration, and recreation equipment.

The injection phase for SFM is quite different from IM as well. Although the machines use an extruder, its design is different from the injection unit with which most molders are familiar. The extruder on SF machines consists of a screw-and-barrel unit that feeds a long manifold. Connected to this manifold are a large number of nozzles, placed strategically through one of a multitude of holes on the platen, that fill one or multiple molds arranged on the opposite side.

With two extruders, these presses can accommodate two different colored materials or two different resin types, producing several parts in one color or resin, and several in another. Each extruder can deliver up to 2800 lb of resin per hour, and shot sizes can reach up to 200 lb for a single part on a 1000-ton press.

|

|

An impressive 1000-tonner will give 20/20 the ability to mold a single part that weighs up to 200 lb. | |

| |

Extruders feed material to a manifold, shown here, to which nozzles are then connected and installed at appropriate hole locations on the platen. |

20/20 Vision

Ernsberger and his partners had a clear idea of what they wanted to do with 20/20 before the first spadeful of dirt was turned over. For one, they believe in buying American, and have a policy of buying only domestic tooling and machines, one that began long before Sept. 11, 2001. The new facility continues a formula of using Maguire blenders and loaders with Uniloy and Milacron molding machines. "We built our former facility with new Uniloy machines and used Milacron IMMs. In five years, we didn't have two weeks of cumulative downtime from those machines," Ernsberger says.

Besides dependability, 20/20 relies on innovation to compete as a custom SF molder. "They [Milacron] have continually upgraded their product lines, and that's very important for a custom molder. We're different from captive, in-house molding operations in that we have to stay cutting edge. People come to us to prove out new designs and gain competitive advantages."

For instance, 20/20 recently worked with Kaymac, a South African injection molder, to prove out a mold and train Kaymac personnel on how to run a Uniloy 500-tonner. "Kaymac had just purchased a press identical to the one we had, and before it arrived, they wanted to become familiar with it," he says. "So we provided the training and invited Uniloy and Snyder Mold to attend the mold trials."

When he first started equipping the new facility Ernsberger looked for the same kind of Milacron IMMs he had used previously, but Milacron, in 1989, had stopped building the model he wanted. The machine combined a 375-ton frame with an extra-wide platen taken from a 500-ton machine. Ernsbergber searched the used machine markets and found two machines. When he went to Milacron to get them rebuilt he learned that the company also had a used machine in stock.

Ernsberger bought that machine as well and had Milacron do a complete remanufacture on all three. The machines were disassembled and cleaned, worn items were replaced, and each was fitted with the latest electronic controls and hydraulics. A modified nozzle allows the machines to do either structural foam molding or high-pressure injection molding for greater application versatility, while the extra-large platen exploits the large-part capabilities of structural foam molding. Machines have either 110- or 165-oz shot size capabilities.

When IMM arrived for this tour, 20/20 technicians were also installing a 1000-ton Uniloy machine with a superwide platen that has single-part capabilities of up to 200 lb. Two 500-ton Uniloys are up and running, and a third was due to be delivered soon. These seven machines and the associated areas needed to store and ship the large parts produced here will take up all of the 40,000 sq ft of floor space.

|

|

Molds are hung on this side of the superwide platen. | |

| |

Flexibility of ejector placement on the back side of the moving platen contributes to the ability to run more molds simultaneously. | |

| |

Each system in the plant has a backup, including nitrogen, chillers, cooling tower, and compressors. |

Plant Specifics

One of the 500-ton presses running at the time of our tour was producing four identical parts, each weighing almost 17 lb. Four molds were hung on the platen, and a bit of each mold hung out on the side. With SFM, however, this overhang is acceptable, thanks to the low pressures. Each mold uses four nozzles to fill each part, and each nozzle opens in a programmed sequence.

As with other custom molders, the advent of the PC and programmable controls has given 20/20 some high-tech answers to its challenges. For example, the timing of resin injection via multiple nozzles is critical to part quality. The opening and closing of nozzles is now programmable on all of its machines, along with how much material each nozzle will inject and how long the shot duration will be. On the 500-tonners, nozzle feed controls can be preprogrammed with one of eight different sequences, or each one can be individually programmed.

At 20/20, a state-of-the-art nitrogen system uses bulk nitrogen supplied to compressors at 6 psi, which then compresses the gas to 3900 psi for use in the extruders on the machines. Nitrogen is introduced into the melt at the third heating zone on the extruder, where it is mixed with the molten resin. This is a critical stage in SFM, and one that is closely monitored.

All of the systems in the plant have a backup so that the plant can continue running uninterrupted during any system failure. This includes the nitrogen compressor, air compressor, chiller, and cooling tower systems.

Up to six different material components can be loaded and blended at the presses for volumes that don't dictate compounding, thanks to weigh scale blenders and a materials handling system (both Maguire). These components can include the neat resin, colorant, regrind, calcium carbonate (a filler), and an additional chemical blowing agent.

With four silos built and four more to be added soon, 20/20 expects to have approximately 1 million lb of bulk material storage capacity. The silos are pneumatically loaded from trucks currently, but will soon be loaded from rail cars when a proposed rail siding is installed. The ability to store large amounts of material is critical, according to Ernsberger, who estimates that the plant uses 2400 lb of resin per hour per extruder.

Cycle times run from 80 seconds to 6 minutes at this facility, and any commodity resin either filled or unfilled can be molded via SFM. However, 20/20 has designed its machines for high throughput using PE and PS materials, so it generally sticks to these two resins.

VITAL STATS Square footage: 40,000 on 36 acres; plans for a 30,000-sq-ft warehouse in spring 2002 |

Contact information |

You May Also Like