Managing the operating costs of injection molding equipment throughout its life cycle is vital to profitability. Appropriate upgrades or replacing older equipment can significantly lower part costs and raise the competitive profile.

June 9, 2010

Managing the operating costs of injection molding equipment throughout its life cycle is vital to profitability. Appropriate upgrades or replacing older equipment can significantly lower part costs and raise the competitive profile.

Typically, a processor's goal is to manufacture products at minimum cost without compromising part quality, functionality, reliability, or delivery. Injection molding requires the use of capital-intensive equipment. With new systems, resin cost is usually the largest part cost contributor, followed by depreciation that is largely dependent on equipment utilization. Selecting new equipment that is optimized for specific parts and production volumes is vital to minimizing part costs.

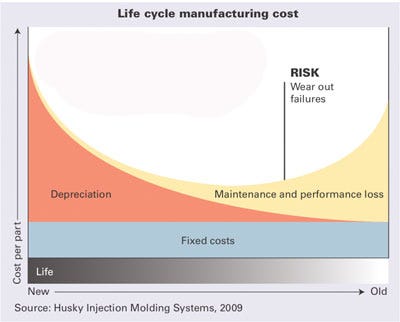

As equipment ages, depreciation costs decline while maintenance- and performance-related costs increase. Minimizing part cost requires maintaining optimal use of equipment while keeping energy, maintenance, and scrap costs low. But all equipment eventually reaches a point at which components come to the end of their design life and begin to fail. At this point, equipment can become increasingly unreliable. This can raise maintenance- and performance-related operating costs, leading to increased part costs (Figure 1).

|

Figure 1. Maintenance- and performance-related costs increase with equipment age, and machines become less reliable. |

|

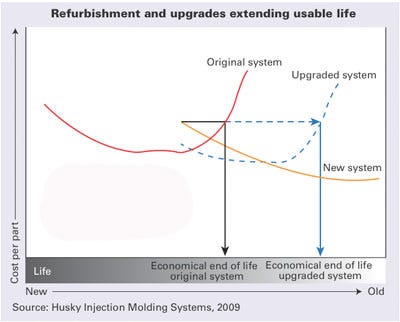

Figure 2. Equipment may become obsolete before it's unusable. |

As products evolve and new technology becomes available, older equipment gradually becomes increasingly less viable to operate. Once manufacturing requirements can no longer be met, or when a more cost-effective solution becomes available, equipment becomes economically obsolete, which can occur before it becomes functionally unusable.

Reinvestment to improve or replace existing equipment is typically triggered by one or more of a variety of factors:

Products evolve and changes are needed to meet market requirements (i.e., lightweighting parts to reduce manufacturing costs and environmental impact).

Existing tooling or equipment is worn and no longer meets quality requirements.

More manufacturing capacity is needed, creating demand for more equipment.

Parts and service are no longer available, making equipment expensive and difficult to maintain.

A competitive threat demands equipment modernization.

What strategy to consider

Determining the best strategy-whether to refurbish, upgrade, or replace existing equipment-can be a challenge, but it's vital to remaining competitive. Refurbishing only to address immediate issues may prove more costly if soon after, the equipment must be replaced due to failure of other more critical components.

Upgrading or replacing existing systems is an opportunity to maximize future profitability. Suitable upgrades generally maximize short-term profitability, effectively extending the life of existing equipment. New systems offer a long-term competitive advantage. Decisions must consider all available information and must be tested against future business objectives, financial status, and market trends (Figure 2).

Financial benefits and considerations need to be evaluated carefully as depreciation costs with new capital expenditures help reduce taxes and improve profitability-specifically, earnings before interest, taxes, depreciation, and amortization (EBITDA). This applies not only to new equipment, but also to major refurbishments and upgrades, provided they meet one or more of the following criteria:

Extends the useful life of equipment beyond 12 months.

Is not a part of routine maintenance nor typically listed in a maintenance manual.

Increases performance by at least 25%.

Is a major integral part of equipment.

Alternatively, all or a portion of refurbishment and upgrade expenditures can be expensed in the current financial year.

In the current economic climate, there are many incentives available to promote new technology and modernization like environmental rebates (from governments and utilities providers, for instance) for improving energy efficiency and implementing green technologies. Apart from the financial benefits, these can yield a competitive advantage in positioning manufacturers to implement leading-edge technology and environmentally friendly solutions.

Significant gains can be achieved by lightweighting a part through conversion of existing tooling combined with upgrading a machine to be more energy efficient. In PET preform molding, a 10% weight savings through lightweighting a 28g part with a 15% machine energy utilization improvement yields a 24% energy reduction per part (considering molding only). An annual volume of 150 million parts per year for approximately one system translates into roughly 370 tons less CO2 emissions. Based on U.S. averages, this is equivalent to about 70 fewer vehicles on the road. Including emissions for resin savings, this increases to around 1500 fewer tons of CO2 emissions per year, which is equivalent to about 290 vehicles.

Determining the right solution

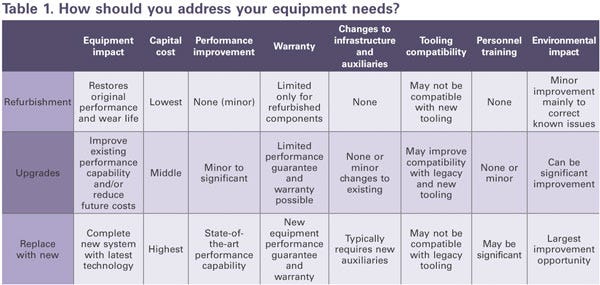

Each situation, part design, equipment, and production requirement is unique and requires in-depth evaluation of multiple options to determine the best solution (Table 1). To help facilitate such initiatives, manufacturers can enlist the help of suppliers to manage injection molding equipment over its entire life cycle, as well as assist in optimizing operations to improve profitability.

|

Consider part design, equipment, and production requirements when deciding to refurbish, upgrade, or replace. |

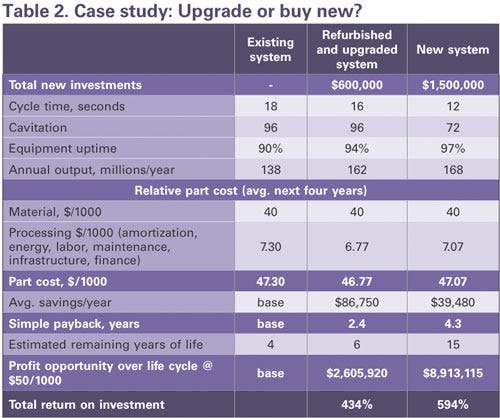

Consider the case of a Husky customer with a fully depreciated 15-year-old preform molding system. The system runs satisfactorily, but spare parts are often hard to obtain and have a long lead time, resulting in many hours of lost production. This manufacturer has several options: to keep running as is, to replace existing equipment with a completely new system, or to have the existing system refurbished and upgraded.

Table 2 considers the relative economic drivers that exist when looking at this customer's capital, finance, and overhead costs, plus amortization, maintenance, and energy. Resin cost savings have been excluded to isolate the benefits of improved equipment performance. Still, resin savings through lightweighting should be included, as it is often the largest cost driver in total part cost and can significantly improve the economic advantages with new or upgraded systems.

|

A Husky customer with a 15-year-old system explored upgrade or buy-new options. |

An upgraded system yields a faster payback than a new replacement system. However, new systems offer the potential for a much greater return for capital invested. Over the course of an expected life cycle, total return on investment (ROI) is 594% (six times) for a new system vs. 434% (four times) for an upgraded system.

If product life is expected to be short (three to five years), the upgrade option offers better profitability as the system will be paid in full before the end of the product life. If product life is expected to go beyond five years, a new replacement system should offer better long-term profitability and competitive advantage.

Ensuring you have an equipment modernization strategy, including implementing appropriate upgrades and replacement of older existing equipment with new equipment, is key to keeping part costs low and maximizing profitability.

Web extra: How can a supplier help?

My company, Husky Injection Molding Systems, offers integrated services to help customers sustain the lowest total part cost throughout the entire product life cycle. Customers can implement one or a combination of these initiatives, which include:

• Optimizing part design through the preform development center.

• Hot runner and preform mold conversion and refurbishment to lightweight and restore part quality.

• Onsite equipment audits and process optimization to assess and improve system efficiency.

• Machine upgrades to modernize and extend installed equipment life.

• Real-time software solutions to monitor and manage equipment and improve equipment efficiencies.

• Manufacturing advisory services to evaluate and implement best-in-class solutions and improve efficiency.

• Proactive maintenance contracts to help ensure continuous optimal equipment performance throughout equipment life.

Greg Cooke is business manager, factories and services for Husky Injection Molding Systems Ltd.

You May Also Like