The injection molder purchased nine machines for its new production facility.

May 17, 2017

Injection molding machine manufacturer Absolute Haitian (Worcester, MA) is exhibiting this week at PLAST-EX, part of the Advanced Design & Manufacturing event in Toronto, where it had some news to share about a sale a few miles south. It announced the installation of nine Haitian and Zhafir machines at the recently opened facility of Tulip Molded Plastics Corp. in Niagara Falls, NY. The 82,500-square-foot production facility replaces the company’s 125,000-square-foot plant built in 1904. Tulip performs injection molding and engineered resin production.

|

Tulip Molded Plastics installed nine injection molding machines from Absolute Haitian in its new plant. |

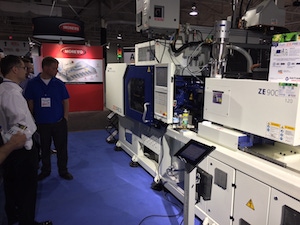

Along with a new power system, auxiliary equipment, chiller, material handling system and central air compressor, Tulip installed four 731-ton Jupiter JUII 6500 two-platen injection molding machines; four 360-ton Mars MAII 3200 servo-hydraulic machines; and one 44-ton Zeres ZE 400 all-electric molding machine. (On the PLAST-EX show floor, Absolute Haitian displayed a ZE 900 machine.)

A part of Tulip’s modernization program involved sourcing injection molding equipment that would meet the company’s requirements for reliability, cost effectiveness, timely delivery and installation, and the ready availability of spare parts and maintenance services, said John Signore, General Manager and project leader. “Our diligence included several visits to Haitian’s Ohio Tech Center,” added Processing Engineer Jason Tanger. “We also visited other molders who had purchased Haitian equipment to assess their experience with machines and support.”

“We were working with a budget, so cost was a major consideration. In the end, it came down to our comfort level with their support,” noted Craig Kellogg, President and CEO of Tulip Molded Plastics. “Absolute Haitian’s shorter lead time for delivery than other companies was also a factor.”

|

Absolute Haitian at PLAST-EX. |

In February 2017, the nine machines were delivered and installed in the new facility. Absolute Haitian was there to fully assist with the final installation, start-up and oversight of initial production. “It went extremely well,” said Kellogg. “We can put any of our molds in a suitably sized machine and they run well. In fact, the up time and cycle time improvement exceeded our expectations. The interchangeability from one machine to another is an advantage,” said Tanger.

Rob Johnson is Plant Manager for the Niagara Falls facility. “When we informed our customers about our plans to move, they of course wanted us to provide them with SPC data to track any variation in the parts being produced on new machines in the new location. We found that our process control is much tighter with less variation than what we had achieved on our previous machines. It has been key in our ability to handle the move and still give customers on-time delivery and quality.”

Tulip serves an array of markets, including automotive and appliances, from three ISO 9001:2008–certified divisions in Milwaukee and Niagara Falls. It has experience molding a variety of engineered resins including PP, HDPE, PE, ABS, Nylon, PS and more.

About the Author(s)

You May Also Like