Users will be able to use in-cavity pressure or temperature sensors to control when the valves open or close, reducing the effects of material changes, according to RJG.

August 27, 2021

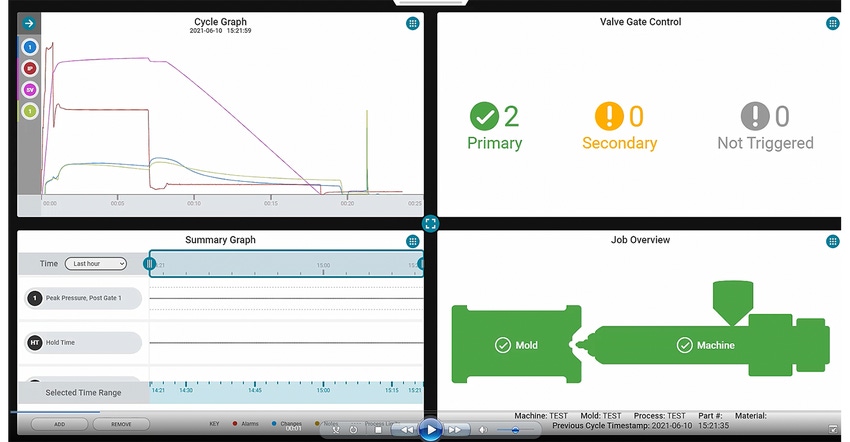

Starting in September, the CoPilot process control system developed by RJG will come equipped with valve gate control. Users will be able to use in-cavity pressure or temperature sensors to control when the valves open or close. This can dramatically reduce the effects of material changes, according to the injection molding technology company based in Traverse City, MI.

RJG's CoPilot injection molding process control allows users to see what's happening to the part and know the moment a process strays off template, resulting in less waste and better-quality parts.

Traceable data proves that each shot complied with a templated process. The CoPilot system also allows users to automatically sort suspect parts, collect data to better understand the root cause of a problem, and access data globally, said RJG.

Next month, the system will be fully equipped with valve gate control technology. The benefits include:

Precise, individual control of flow fronts in a large multi-gate cavity;

increased control over the removal or moving of knit lines;

precise, individual control of flow fronts in cavities making different parts;

precise, individual control of flow fronts in cavities making the same parts, where cavity fill balance is an issue;

improved long-term part consistency in both family and multi-cavity molds;

maximized uptime, process capability, and performance.

Users are able to view a snapshot of how valve gates are functioning from the overview screen. More detailed information can be accessed by clicking into the valve gate screen, including when each specific valve gate opened, when it closed, and if it didn't trigger.

Applications include large, complicated parts that require multiple valve gates and multi-cavity tools with a gate for each cavity.

About the Author(s)

You May Also Like