At the Fakuma trade show in Friedrichshafen, Germany, next month, Engel (Schwertberg, Austria) will demonstrate how intelligent components and networking can elevate machines and production cells to a new level of process optimization. The concept will be illustrated through innovative applications for the automotive, technical molding, teletronics, packaging and medical sectors at booth 5204 in hall A5.Under the banner of Inject 4.0, Engel has designed its booth in the image of a so-called smart factory with three core elements:

September 16, 2015

At the Fakuma trade show in Friedrichshafen, Germany, next month, Engel (Schwertberg, Austria) will demonstrate how intelligent components and networking can elevate machines and production cells to a new level of process optimization. The concept will be illustrated through innovative applications for the automotive, technical molding, teletronics, packaging and medical sectors at booth 5204 in hall A5.

Under the banner of Inject 4.0, Engel has designed its booth in the image of a so-called smart factory with three core elements:

smart machines that boost process capability and quality via self-adapting, decentralized systems;

smart production to ensure high levels of productivity thanks to horizontal and vertical data integration;

smart services that improve availability thanks to proximity and the use of remote maintenance tools.

During the run of the show, all machine data will be collected on a central computer. The Engel e-factory MES software running on the computer enables job scheduling, querying of the injection molding machines and the creation of quality reports and documentation. At the same time, visitors will gain insights into the Engel e-connect online customer portal through which spare parts can be sourced and ordered and service requests can be submitted.

|

Engel will showcase Clearmelt technology for automotive |

The iQ product family, which enhances process stability by continually analyzing the plasticizing and molding process and making automatic adjustments in case of deviations from targets, and e-flomo, which autonomously ensures a constant supply of cooling water, also will be featured at the booth.

Key applications demoed by Engel at Fakuma include the following:

Clearmelt technology allows the economical manufacture of decor elements with wood veneers for automotive applications. The veneers are back-injected with a thermoplastic in a single step and coated with transparent polyurethane to protect the surface. First introduced in 2009, the first serial application is imminent at HIB Trim Part Solutions. Fakuma visitors will get a preview of the technology, as the premium wood decor elements are molded in a two-cavity mold on an Engel duo 3550/650 combi M injection molding machine.

In collaboration with partner companies Schneegans Freudenberg Silicon and Elmet, Engel will produce diaphragms made of glass-fibre-reinforced polyamide (PA) and liquid silicone on a victory 200H/60L/140 combi injection molding machine with an integrated viper 40 linear robot. In each cycle, the robot removes eight finished parts and transfers the PA base bodies to the second set of cavities in the 8+8-cavity serial mold, where they are overmolded with silicone. While LSR processing is going on, a new set of base bodies is created.

A first for the company at Fakuma, Engel will present an integrated, fully automated process for manufacturing thermal switch housings, starting with the raw material and culminating with the 100% tested and labeled metal/plastic composite parts. The core of the production cell is an Engel insert 60V/35 single vertical machine. A strip uncoiler, press module and processing module for thread tapping are positioned upstream; downstream, there are quality controls, a laser marking system and another press module.

|

The Beck-Flex automated IML system will make its global debut at the Engel booth. |

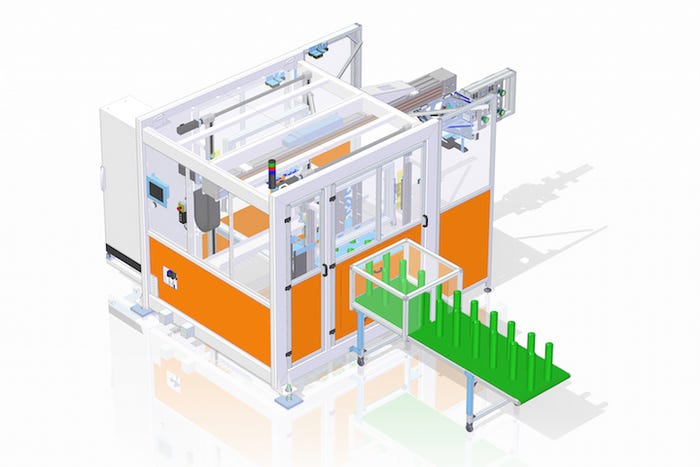

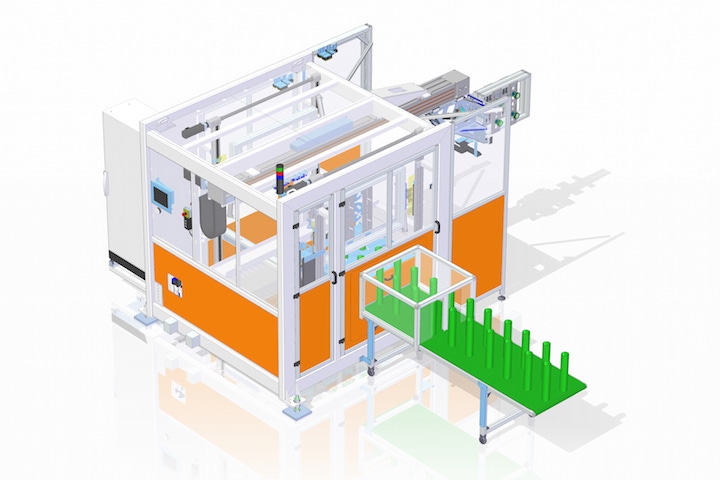

In the packaging section, Engel will run an e-motion 440/160 producing 155-ml round containers with an integrated tamper-proof seal using a four-cavity mold from Otto Hofstetter. Thanks to in-mold labeling (IML), the production cell will output ready-to-fill packaging. IML automation is implemented by Beck Automation. The new Beck-Flex system will have its global premiere at the Engel booth.

In the medical section of the booth, an Engel e-motion 170/80 TL will be producing needle holders for 1-ml safety syringes in a 16-cavity mold from Fostag Formenbau. The filigree polystyrene parts, with a shot weight of 0.08 g, are designed with a predetermined breaking point that makes it impossible to re-use the disposable syringes.

Fakuma runs from Oct. 13 to 17 in Friedrichshafen, Germany. For more information about the international trade fair for plastics processing, read "What makes Fakuma tick?"

About the Author(s)

You May Also Like