It's show time at the Milacron (Batavia, OH) booth—the company's largest booth ever, by the way—at NPE (W-2703), and what a lineup! For the first time, Milacron is bringing all of its technologies together under a unified brand into what Milacron says "reflects the company's transformation into the industry's most comprehensive integrated plastics solutions provider."

March 19, 2015

"Collectively, we have developed more products in the last two years than our product brands have in the last 10 years," stated Tom Goeke, CEO of Milacron. "We want customers calling us with their toughest problems and wildest ideas; it's our business to make their aspirations come to life."

The new Milacron PET system is one of the company's latest show-stopper technologies. This servo-hydraulic preform molding system with industry-leading dry cycle times, low energy operation, options for post cooling functions and ease of service, is sure to wow attendees.

For the first time, Milacron will be molding Klear Cans, a "revolutionary co-injection method" that enables plastic containers to replicate the benefits of metal and glass storage solutions, said Milacron. Pioneered by Milacron's most recent acquisition, Kortec (now Milacron Co-Injection), Klear Can features co-injection technology that elevates product packaging possibilities. The Klear Can is being molded on a Ferromatik 280 co-injection machine on a four-cavity work cell in less than eight-second cycles from a mold built by StackTeck.

If you want to see some really big parts being molded, watch the Ferromatik 580 co-injection mold industrial containers from a mold built by moldmaker Calframax. The five-gallon plastic pails are molded using 50% postconsumer recycled material at sub 15-second cycles.

The new Maxima Performance Series will debut at NPE, a machine line designed and built to address market demands for high-performance, low-energy usage, precision and flexibility. Built on the success of the Maxima 2-platen platform, the enhanced Performance Series is available from 450 to 1000 metric tons. It delivers 33% faster dry cycle times and consumes 70% less energy than competing systems, and features the widest platens in each tonnage range, a precision greaseless clamp guided on linear bearings and integrated auxiliary control.

|

Fusion G2 Series for automotive and large-part molding. |

There's also a really cool Roboshot 150 LSR molding cell for multi-material molding of thermoplastic and thermoset materials in a single machine that is being unveiled at NPE. Working in partnership with LSR moldmaker Roembke, the new all-electric system will produce an automotive diaphragm that uses a combination of nylon with liquid silicone rubber (LSR) over-molding.

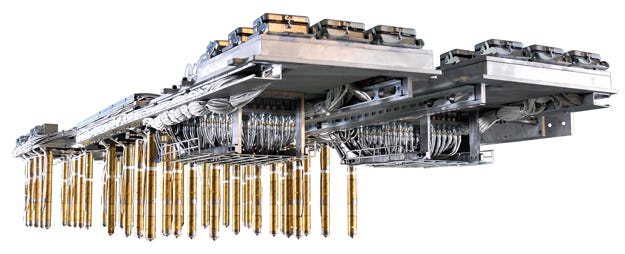

If you want to change it up and see the latest in high-efficiency blowmolding, Milacron has that, too! Milacron's new hybrid machine, the Uniloy IBS 199-3, was converted to a hybrid design to reduce energy with a direct electric screw drive and servo hydraulic injection for precise shot-to-shot consistency. The Uniloy work cell features a 20-drop, in-line Mold-Masters Axiom Synchro-Plate Valve Gate system that is rheologically balanced along with a 33-zone integrated TempMaster iM2 Hot Runner Temperature Controller for precise control.

Also check out Uniloy's newly released designs that enable customers to work around their unique requirements while staying with their current downstream equipment with little or no changes. Designs that allow the lightweighting of containers while maintaining or improving their integrity and performance will also be of interest to blowmolding engineers in attendance.

For attendees interested in what Milacron offers in medical molding, visit the Roboshot 220 Medical Cell that will showcase the new Mold-Masters Summit-Series premium stainless-steel hot-runner line, offering four times less thermal variation from set point, compared to the typical thermal variation seen in a nozzle with a heater band.

There's more to see at this huge display:

GPAK 45 Groove Feed extruder that constructs polyethylene pipe.

Magna T225 Automotive Light-Weighting system that utilizes MuCell microcellular foam molding technology.

Large Mold Bases from DME featuring plate lengths up to 90 in. (2300 mm).

MUD (Master Unit Die) quick-change aluminum inserts fabricated from an Alumold 500-mold plate.

DME Pre-Machined Insulator sheets.

Ceramic fiber deburring and surface-finish tools for moldmakers.

Mold-Masters Summit series stainless steel hot runners for premium applications.

Fusion G2 series for automotive and large-part molding.

Vision for automotive lens molding.

SmartMold—a "revolutionary new technology" that enables molders to see details about their molds that were previously impossible.

Visiting Milacron is sure to be an educational experience! Check it out!

About the Author(s)

You May Also Like