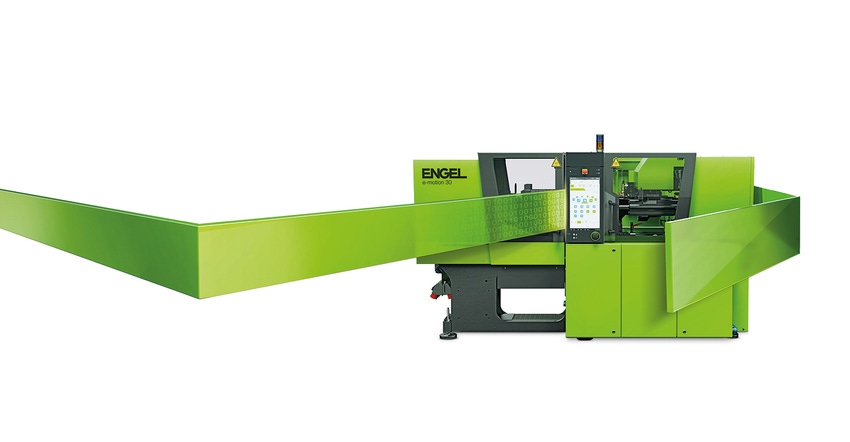

Through Engel’s pay-per-use option, customers are billed on a per-unit or machine operating time basis.

December 14, 2022

Plastics processing machinery maker Engel now offers customers a pay-per-use option in lieu of buying a new injection molding machine outright.

The plan allows processors to reduce investment risk while boosting production flexibility, said Austria-based Engel in making the announcement. Because it avoids tying up significant capital in a machine purchase, which typically requires approval, the procurement process can be accelerated, added Engel.

Customer cost is a function of the machine’s utilization level. A unit price is agreed upon, based either on a per-unit basis or machine operating time.

All production cells delivered via the pay-per-use model feature the online support and remote maintenance tool e‑connect.24 and are regularly maintained by Engel service technicians. When needed, Engel technicians can start troubleshooting immediately. Maintenance work can be planned at an early stage to minimize downtime. The e‑connect.24 tool captures machine utilization rates as the basis for billing.

At the end of the contractual term, the customer has the option of purchasing the machine or sending it back to Engel, where it will become part of the inventory of the group’s pre-owned machine company. This also contributes to sustainability, since the program maximizes the service life of the injection molding machine, said Engel.

The financing partner backing the new pay-per-use model is linx4 GmbH, which is headquartered in Vienna. Engel said it is the first supplier in the injection molding machine field to offer customers this flexibility.

You May Also Like