"We are noting an improved project situation both in the established markets in Central and Eastern Europe, but also from up-and-coming markets such as South America and the Near and Middle East," noted Peter Oswald, head of product management at the Munich-based company.Oswald also noted stronger demand for complete systems. In addition to providing individual machines, the company has been developing complete extrusion systems for processing PVC into window profiles, as well as for processing polyolefin for technical profiles.

September 15, 2014

"We are noting an improved project situation both in the established markets in Central and Eastern Europe, but also from up-and-coming markets such as South America and the Near and Middle East," noted Peter Oswald, head of product management at the Munich-based company.

Oswald also noted stronger demand for complete systems. In addition to providing individual machines, the company has been developing complete extrusion systems for processing PVC into window profiles, as well as for processing polyolefin for technical profiles.

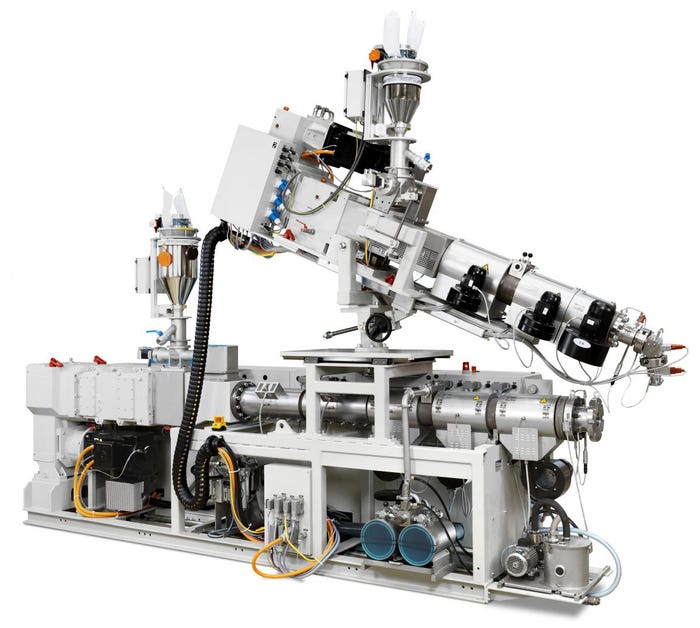

The company has noted increased interest in processing natural fiber-reinforced materials. These materials allow for the use of renewable resources to partially replace expensive plastics. Pictured is a KraussMaffei Berstorff coextrusion model for processing recycled materials and fillers.

The company said its twin-screw and single-screw systems are ideal for producing the technical profiles needed by the automotive industry, construction, and other industries.

Its coextrusion combinations, Oswald said, "enable profile manufacturers to use recycled materials and fillers in what is called core, layer, or combination technology, and thereby substantially contribute to lower material costs."

Increasing price pressure and raw material scarcity is forcing manufacturers to look for new ways to process more cost-effective materials while still manufacturing a premium quality finished product with a perfect exposed face. KraussMaffei Berstorff said its variety of combinations accommodate practically every customer-specific production requirement, including materials, application, and space.

The company's offering includes small parallel twin-screw laboratory extruder. It allows the manufacturer to test formulations with low material consumption. Its output is 15-40 kg/h and it is suitable for all commercially available rigid and flexible PVC mixtures. Exchanging corresponding screws enables it to produce pipes or sheets.

About the Author(s)

You May Also Like