December 11, 2013

Lightweighting. Lightweighting. Lightweighting. It seems almost every plastic packaging story mentions lightweighting in some shape or form.

Sometimes it seems like lightweighting is a bad word when it comes to packaging. IHS just released a report about the PET market, claiming that continued lightweighting of bottles and packages, driven by both economics and the need for an improved environmental footprint, coupled with an increased use of recycled material, have been the main drivers behind the poor demand growth for PET. While many signs clearly indicate that lightweighting is a factor, another report from Canadean claims that lightweight packaging may actually boost the consumption of plastics in the U.S.

Americans will be using 32,850 million more rigid plastic and flexible packs in 2017 than they were in 2012, making these the fastest-growing segments in the U.S. packaging industry, Canadean stated. The requirement for greater convenience and cost-effectiveness will drive the use of lightweight flexible and rigid plastic packaging with innovative pack shapes, closures and dispensers.

|

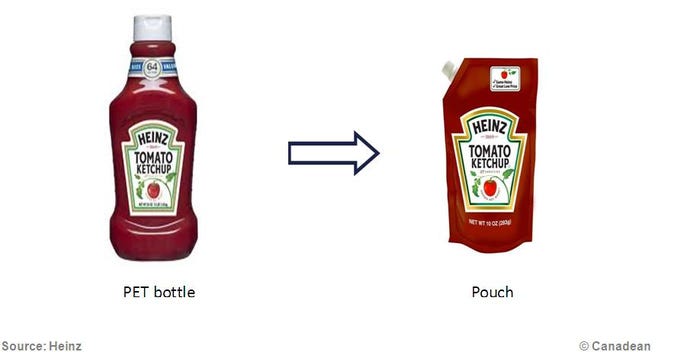

In 2012, Heinz developed flexible pouch packs to complement its traditional rigid plastic bottle formats. |

"The key advantage of flexible packaging is its low intrinsic weight, which ensures lower transportation overheads and reduces the overall supply chain costs. These incremental weight savings not only provide cost benefits, but also reduce transportation costs and overall breakages," said Dominic Cakebread, director of packaging services at Canadean, in a news release.

Although there is a lot of pressure to reduce packaging materials weights and gauges/thickness, the finished pack itself is still expected to have the same technical performance characteristics and functionality as existing packaging formats, which makes the production of lightweight packaging materials ever more technically demanding.

New technologies support the growth of plastics

Bioplastics made from agricultural by-products, is one of the most recent innovations within the plastic packaging industry. The new materials can offer manufacturers the opportunity to reduce carbon footprints and better protect the environment through a reduced dependence on petro-chemicals and other mineral rich packaging materials.

|

The haircare brand Pantene has been made available in bottles of sugarcane-based plastic. |

|

Coca-Cola has set the goal of using its plant bottle technology across its entire range of bottled beverages by 2020. |

Such materials claim to offer important environmental benefits, reducing fuel consumption by 70% per ton and releasing significantly less carbon into the atmosphere. However, there also exists environmental controversy over the use of valuable and often scarce agricultural land for growing biopolymers instead of food, which longer term could lead to substantially higher food prices.

Manufacturing processes lead to cost savings for producers

While the flexible packaging industry offers considerable growth opportunities, it faces challenges such as the unstable prices of raw materials and the lack of skilled labor. Multi-tasking packaging machines enable packaging companies to achieve efficient use of resources and minimize their costs.

So yes, while lightweighting does produce less material and in the case of PET, may hurt demand, it can also help influence brands to make a switch to plastics. For instance, at the Global Plastics Summit Dow Chemical's Greg Jozwiak, commercial VP for North America packaging, said that trends supporting the conversion to plastics include lightweighting, food preservation, convenience features and waste reduction, Jozwiak said.

"My perspective is that shale gas presents an opportunity to collaborate and innovate for growth - to reshore the manufacturing of film bags; replace traditional material in packaging and export finished goods," he said. "We have the opportunity to build up the industry beyond the will of the existing market."

So it may sound cliché, but looks like when it comes to lightweighting for some applications, less really is more.

About the Author(s)

You May Also Like