In a collaboration with a group of leading Japanese corporations, Tokyo University has developed two types of low-cost, high-performance CFRTP (carbon fiber-reinforced thermoplastics) prepregs for the mass production of ultra-lightweight cars which can be manufactured in fast molding cycles and are recyclable to boot.

May 30, 2012

In a collaboration with a group of leading Japanese corporations, Tokyo University has developed two types of low-cost, high-performance CFRTP (carbon fiber-reinforced thermoplastics) prepregs for the mass production of ultra-lightweight cars which can be manufactured in fast molding cycles and are recyclable to boot.

|

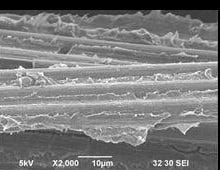

Specially-treated carbon fiber and modified resins are employed in new auto composite |

|

New composite materials boast superior formability. |

The first one is a discontinuous CF-reinforced isotropic prepreg and the second one a continuous CF-reinforced prepreg. The matrix resin is primarily PP (polypropylene), but PA (polyamide) can also be employed. The specially surface-treated CF and modified resins developed for these prepregs provide high strength, energy absorption, formability and recyclability. A full impregnation method was developed to shorten the molding cycle to a minute. Joining, repair and recycling technologies utilizing the thermoplastic nature of the matrix materials were also developed.

These CFRTP prepregs will reportedly enable weight reduction in automotive bodies of 40-70%. The discontinuous CF-reinforced isotropic prepreg is suitable for complex parts and the continuous CF-reinforced prepreg for primary structure parts such as frames. Their most notable feature is their ductile fracture behavior without significant delamination. Their tough nature not only brings a high energy absorption capacity but also provides more flexible manufacturing methods for composite structures.

The material development phase has been completed and the project has proceeded to the application phase. The team is sharing material data and samples with major Japanese automobile manufacturers. Prototype design and trial manufacture are in progress.

With these innovative technologies, it is estimated that 100 kg of CFRTP parts will equip 10 million passenger cars annually by 2030. Hence, the potential market demand for CF is estimated at one million tonnes by 2030.

Corporate partners in the project are carbon fiber suppliers Toray Industries, Mitsubishi Rayon, and Toyobo, together with molder Takagi Seiko. The team won a JEC Innovation Award in the Automotive Category that will be presented at the upcoming JEC Asia show in Singapore to be held June 26-28, 2012.-[email protected]

About the Author(s)

You May Also Like