Film and sheet extrusion systems supplier Macro Engineering & Technology Inc. has added the option of individual layer gas foaming to its barrier blown film coextrusion lines. The company says the individual layer foaming option allows processors to create a wider range of products by manipulating different foamed layer combinations within the coextruded film structures.

September 24, 2014

Film and sheet extrusion systems supplier Macro Engineering & Technology Inc. has added the option of individual layer gas foaming to its barrier blown film coextrusion lines. The company says the individual layer foaming option allows processors to create a wider range of products by manipulating different foamed layer combinations within the coextruded film structures.

Macro's blown film coextrusion systems are used to produce high barrier films up to 11- layers and up to 3m wide using a variety of materials including PA, EVOH and PVdC. The films produced are most typically used in food and medical packaging applications.

|

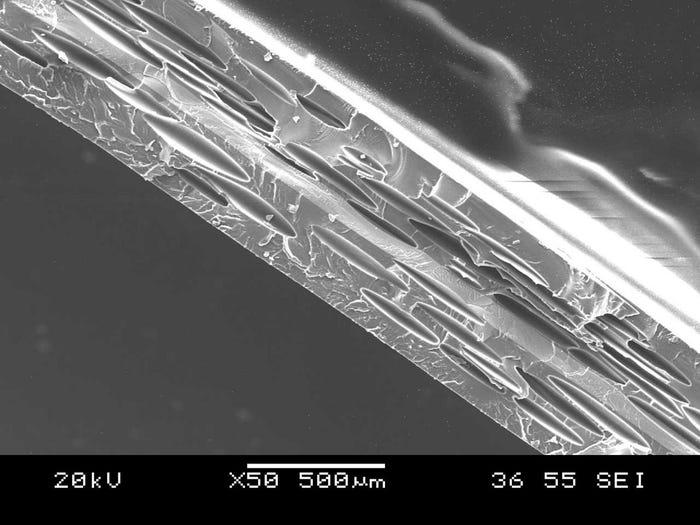

SEM (scanning electron microscopy) image of a coextruded barrier film with two foamed layers |

Foaming can reduce weight, which can reportedly lead to raw material savings and can also create properties in the film such as improving thermal and sound insulation, and opacity can be obtained without using fillers.

Earlier this year, Macro announced the addition of individual layer foaming technology to its cast barrier film lines along with news of a 7-layer cast line installation in Europe that produces high barrier films with layer foaming in two of the seven layers.

Similar to the cast technology, the blown system features individual layer foaming that is achieved with nitrogen gas injection through a proprietary feedblock. The configuration of the line allows it to be operated with or without foam injection, allowing the film producer to easily switch between foamed films and conventional multilayer film production without changing machinery.

Macro claims that the addition of individual layer foaming to its blown film coextrusion systems broadens the possibilities of end-use applications by producing barrier films that are stiffer and thicker without increasing materials costs. For instance, the rigidity of the foamed films makes them suitable for stand up pouches and thermoformed trays.

Macro is currently building a 9-layer blown film line with individual layer foam technology that will be delivered to an undisclosed film manufacturer in Europe. The line will produce high barrier films and can foam individual layers or several layers together, depending on the application.

About the Author(s)

You May Also Like