BondLynx adhesive permanently joins difficult-to-bond polymers to themselves and other materials via bis-diazirine chemistry.

September 15, 2021

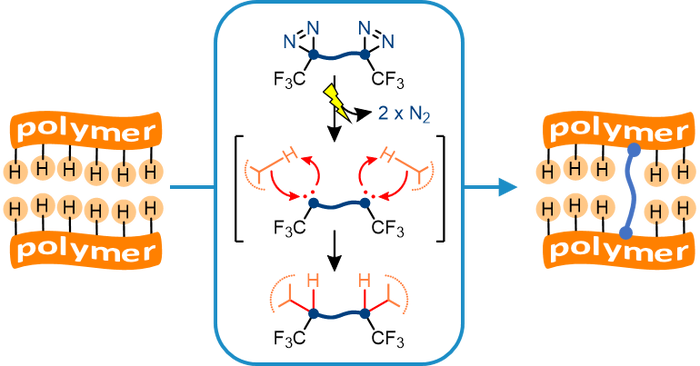

An adhesive that permanently adheres difficult-to-bond polymers to themselves and other materials has been introduced by XlynX Materials. The BondLynx adhesive creates covalent chemical bonds between polymer chains via bis-diazirine chemistry, permanently cross linking them together through strong carbon-carbon bonds.

Conventional adhesives typically take advantage of mechanical forces to hold materials together. The covalent bonds formed by BondLynx resemble the structure of carbon atoms in strong carbon-carbon bonds, said XlynX Materials in its announcement. Once BondLynx has been applied to a polymer, the cross-linking process can be initiated via heat, ultraviolet or visible light, or an electric field, depending on the specific demands of the manufacturing process.

|

BondLynx adhesive creates covalent chemical bonds between polymer chains through bis-diazirine chemistry. |

"What's really amazing about BondLynx is that it can ‘glue’ virtually any plastic to any other plastic,” said Jeremy Wulff, PhD, Professor of Organic Chemistry at the University of Victoria in British Columbia, Canada. "BondLynx acts by inserting itself into the carbon-hydrogen bonds that are present in almost every commodity polymer. The potential applications are limitless," said Wulff.

XlynX reports that BondLynx has successfully undergone adhesive testing on a range of polymers and polymer-metal combinations. Even elastomers and damp surfaces can be bonded with BondLynx, opening broad opportunities for novel medical and dental applications, said the company.

In addition to being used directly as a polymeric adhesive, BondLynx also can be applied to polymer textiles to link and strengthen fibers. It has proven effective in strengthening ultra-high-molecular-weight polyethylene (UHMWPE) fabrics for ballistics protective equipment and wind sport applications. After testing the glue, the CEO of PRE Labs, a manufacturer of body armor products, remarked that the “cross-linking agents can significantly enhance the tear and perforation resistance along with mechanical properties of high-performance fabrics.”

Researchers at the University of British Columbia, University of Alberta, McGill University, and industry labs have already begun testing the adhesive.

Samples of BondLynx for testing and research purposes are available by request from XlynX Materials.

The scientific research that led to the development of BondLynx is described in a 2019 paper published in Science.

About the Author(s)

You May Also Like