Ultramid Vision enables parts that are transparent and highly resistant to chemicals, with heat resistance and scratch-proof properties to boot

October 11, 2017

Germany’s BASF has developed a semi-crystalline polyamide that allows light to pass through largely unhindered. Ultramid Vision combines very high light transmission with low light scattering. This makes it the world’s first semi-crystalline polyamide for semi-transparent or transparent components in chemically challenging environments.

Moreover, the unique polyamide is ultraviolet (UV) light and temperature resistant, scratch-proof as well as suitable for flame-retardant requirements. Ultramid Vision can be used in various application fields: It is recommended especially for parts for visual check, illumination or light design. Ultramid Vision presents a versatile alternative to commonly used materials such as amorphous aliphatic polyamides, polycarbonate or styrene-acrylonitrile copolymers. The new polyamide is globally available for sampling.

Ultramid Vision has physical and thermal properties which are similar to conventional unreinforced polyamide 6 compounds. However, it stands apart from these compounds significantly thanks to its exceptional visual properties. While semi-crystalline standard polyamides are nearly opaque, i.e., is visually hazy, at a wall thickness of only one millimeter, one can see easily through parts made of Ultramid Vision at wall thicknesses of up to several millimeters. Even if components made from Ultramid Vision are exposed to elevated temperatures and moisture, the haze and transmission values hardly change compared to values exhibited immediately after molding.

|

The world’s first semi-transparent polyamide unlocks a wide variety of application potential in chemically demanding environments. |

Ultramid Vision is also suitable for applications involving direct exposure to sunlight. The UV resistance was tested both for indoor use and under outdoor weathering conditions using conventional accelerated weathering tests. Ultramid Vision also shows excellent stress cracking resistance to sun screen, cleaning agents and solvents as well as fats and oils.

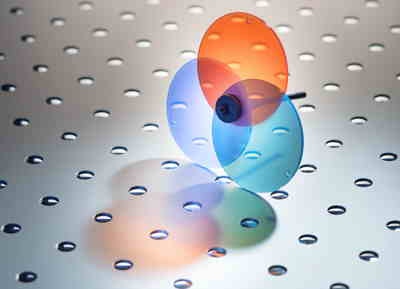

In addition to the uncolored base grade Ultramid Vision B3K un, there is the option of producing specially customized grades featuring diffuse light scattering along with high transmittance. Customers can also obtain specially colored grades. Alternatively, Ultramid Vision can be colored with polyamide-based color masterbatches which can be procured from BASF Color Solutions. In addition, the highly light-permeable Ultramid Vision can be combined with other polyamide materials in multi-component injection-molding processes to produce multifunctional parts with transparent or illuminated sections.

Ultramid Vision is particularly suitable for applications requiring visual checks such as level indicators. The new polyamide can also be used for shockproof and chemically resistant covers for lighting elements. Further application areas include back-lit switches and buttons or diffusely scattering light covers in chemically aggressive environments.

Because of the virtually unlimited scope for coloring Ultramid Vision with low-migration and lightfast colorants, luminous color effects can be achieved that offer a wide range of design possibilities for creating design objects or design features.

About the Author(s)

You May Also Like