New Canadian research finds that mold can infiltrate and weaken bio-composite materials, affecting their strength and durability.

January 12, 2018

Fibers such as flax, hemp, cellulose nanofiber, and kenaf have been used as reinforcements in composite materials for automotive applications, with kenaf in particular having made commercial inroads. However, a word of caution has been sounded by the University of British Columbia’s Okanagan School of Engineering, which says that mold of the fungal type is proving increasingly important in the domain of engineering materials and can lead to early deterioration and structural failure. This is especially the case as manufacturers adopt more bio-derived materials in the drive toward a greener future, explains researcher Bryn Crawford.

At UBC’s Okanagan campus, a multi-disciplinary team of researchers from the Composites Research Network and the Department of Biology, in collaboration with MIT and the National Research Council of Canada, have been studying the development and application of bio-sourced composites—specifically flax and hemp fibers.

|

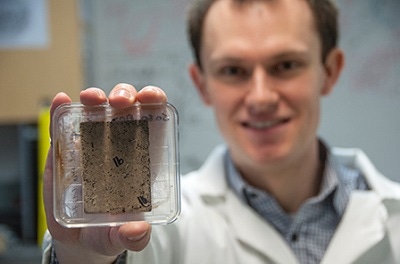

UBC researcher Bryn Crawford holds a sample sheet made with flax bio-waste. The black spots on the sheet indicate mold growth. |

These materials are plentiful in Canada and can be mixed with other materials to create cheaper, recyclable, and effective composite material products that are used by a range of industries, including in transportation.

“Canada has a lot of biomass that can be used to produce materials that are both light and inexpensive,” explains Crawford. “We’re looking at ways of using biomass in engineering, but there is a level of natural deterioration in these products that is still not fully understood.”

In the study, researchers conducted a number of experiments to determine if and when mold will grow on bio-materials and how it might affect the final product.

“When we bring microbiology into engineering, it raises some extra questions; some questions we’ve never thought about before,” says Crawford. “But because we’re now using biological matter, we have to think of fungal growth and how this fungal growth will affect a product’s performance.”

The research team examined flax and hemp fibers alongside other natural materials to determine what would happen over time to these fibers. They created ‘fiber sheets’ and then added fungi to some, water to others, and left another group of sheets untreated.

Crawford says they are not surprised that the materials grew mold; the idea of the project was to determine the types of environment where the fungal spores would grow and then test mechanical properties of the affected materials. The team conducted a variety of tests examining them for strength, stiffness, or the amount of energy that can be absorbed before the bio-composite materials failed. They also used scanning electron microscopy to take an extreme close-up of the interior of the sample to determine fungal growth patterns, examine fractures, and failure zones.

“It was a huge experiment and we found that in both the hemp and flax fibers, when no fungi were added, we still had fungi growing,” Crawford adds. “Basically, when raw natural fibers are exposed to high relative humidity, mold will grow and the potential for premature structural failure can occur.”

Crawford says that this susceptibility to mold growth is important for supply chains and factories to understand and manage, in order to ensure they’re creating durable and robust products. “Bio-composites made from natural fibers are good for both the environment and the economy and could help usher in the next revolution in manufacturing. More multi-disciplinary research of this kind is vital to producing high-quality and durable bio-composite materials that help make that leap.”

About the Author(s)

You May Also Like