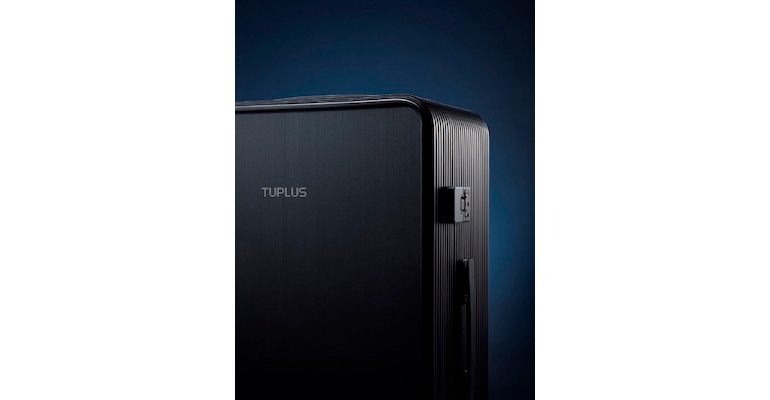

Sturdy and stylish suitcase from Chinese brand Tuplus has front and back shells molded from polycarbonate-carbon fiber composite.

June 17, 2020

Chinese luggage brand Tuplus has released a carbon fiber suitcase featuring front and back shells made of Maezio thermoplastic composites from Germany’s Covestro, boosting impact performance while elevating design and style.

The new model features a creative multi-material design concept: The structural frame in the center is made of aluminum and magnesium alloy, while the front and back shells have been given the look of carbon fibers. It is also designed with an advanced lock system featuring the absence of rivets and screws, giving it a smooth, minimalist finish.

|

Polycarbonate-carbon fiber composite plays key roles in aesthetics and strength of luggage. Image courtesy of Covestro. |

Despite the dramatic decrease in travel due to the corona crisis, Tuplus believes the travel industry will bounce back steadily as travel restrictions are eased in China and across the world. “People haven’t changed in that they still want to travel, but we need to adapt to the new times ahead and to the new needs of tourists to feel safer,” says Catherine Jiang, President & CEO of Tuplus. “High-quality materials are always at the heart of our design concept because we know our customers rely on them for travel safety and security. Covestro’s Maezio composites have allowed us to take advantage of the superior strength and premium value of carbon fiber, to offer our customers enhanced protection and an entirely new travel experience.”

On and off airplanes, in and out of car trunks, natural wear and tear – luggage needs to be robust. Maezio thermoplastic composites are based on a polycarbonate matrix system. The intrinsic toughness of polycarbonate has made it a staple material for hard-shell suitcases for decades. Carbon fiber reinforced polycarbonate composites take stiffness and impact resistance to a new level. They can reduce the risk of damage and deformation, even when compared to metal, without adding weight.

Rigorous safety tests ranging from drop and tumble tests to falling ball impact tests have shown better impact resistance of composite shells compared to aluminum. This means the material can better protect articles in the luggage against perils, in particular sensitive equipment like cameras and high-end electronics.

A suitcase built to last also needs to look good. With a natural, unidirectional carbon fiber appearance, Maezio composites break away from the traditional woven look of carbon fiber, while striking a chord with natural materials like wood in its looks and aesthetics.

Performance and design are only the starting points for luggage manufacturers however, as they need to integrate new materials which can also be manufactured cost-efficiently at scale. Despite its popularity, carbon fiber luggage is known to be laboriously hand-crafted, driving up costs and making them difficult to scale.

Maezio materials on the other hand, are thermoplastic composites, which can be thermoformed efficiently at high yield rates and low cycle times, making them ideal for mass production. Not all carbon fiber suitcases need to be thermoformed however – the unique design of the front and back shell structures of Tuplus luggage allows composite sheets to be integrated directly into the production line and assembled after proper cutting and coating. This design approach is unique to expedite the scaling of carbon fiber suitcases.

“We believe our thermoplastic composite solutions will accelerate the adoption of carbon fiber composites in luggage thanks to their unique performance, aesthetic and production advantages,” says Lisa Ketelsen, Head of the thermoplastic composites business of Covestro. “Meanwhile, we’re also working on thermoformed, 3D luggage cover solutions to make composites available for a wide range of suitcases and allow more and more consumers to enjoy the performance and lifestyle benefits of composites.”

About the Author(s)

You May Also Like