Encapsulated physical foaming agent targets shoe soles, underbody coatings.

November 3, 2020

Materials such as thermoplastic elastomers (TPEs) and thermoplastic polyurethanes (TPUs) cannot be processed by conventional chemical or physical foaming due to their low melt strength. In such cases, microspheres from Rowa Group subsidiary Tramaco’s can offer an adequate solution.

These microspheres consist of a physical foaming agent which is encapsulated in a polymeric shell that expands substantially under the influence of heat, whilst retaining the increased volume during cooling.

|

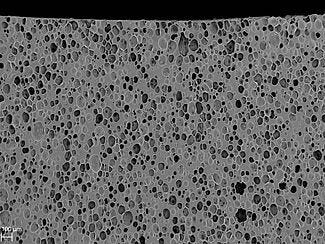

Very low densities and highly homogeneous, closed cell foam structures can be produced |

Diverse fields of application for these agents include TPU shoe soles, coatings, underbody coatings, wall coverings, insulation materials and liquid and solid silicone rubbers (LSR and HTV (high temperature vulcanization)). Very low densities and highly homogeneous, closed cell foam structures can be produced using the microspheres.

Tramaco offers a wide range of expandable microspheres as powder (for plastisols) and polymer-bound masterbatches in granulated form (for injection molding applications). In some applications an optimal result can be reached by combining microspheres and conventional chemical foaming agents. Appropriate Tracel chemical foaming agents from Tramaco are available for such applications.

Pre-expanded microspheres are a brand-new addition to Tramaco’s portfolio. Application of these ultra-light fillers, with densities below 30 kg/m³, can create cell structures in materials which do not allow expandable microspheres or conventional chemical foaming agents in their processing operations, such as paints, lacquers, coatings and thermoset resins.

About the Author(s)

You May Also Like