Sabic PP-UMS (Ultra Melt Strength) resin reportedly represents a completely new generation of melt-strength PP.

November 30, 2017

Close collaboration with its partners in the value chain has enabled Sabic to build up a large bank of knowledge on foaming technologies, and to develop a dedicated, diverse foam portfolio, applicable in almost all industrial applications. The company is now adding to this portfolio with the launch of its Sabic PP-UMS (Ultra Melt Strength) resin series.

|

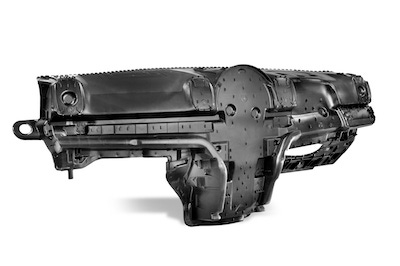

Sabic’s foam grade resins are used in diverse application including PP foam for automotive parts (above) and food packaging (below), and LPDE foam for thermal pipe insulation (bottom). Sabic also says it has created considerable interest in the development of blends of LDPE with polyolefin elastomers and plastomers (POEs and POPs). |

|

|

Sabic’s new resin is said to be unique in the market, with a melt strength of more than 65 cN and outstanding foamability. It can be used by all industry segments as a building block to develop new foaming solutions that enable “an unprecedented level of lightweighting,” according to the supplier.

“Looking to the future of lightweighting, we see that foaming is a key technology to push the boundaries and create even more down-gauging opportunities in the industry. For this reason, our global teams are busy developing the next generation of foamable resin solutions for the market. These solutions can be used in many processing technologies to best meet the unmet needs of the value chain,” said Frank de Vries, Sabic’s global Foam & Lightweight Leader.

The new Sabic PP-UMS material can be used to enhance lightweighting in the automotive, packaging, and building & construction markets. The material has been evaluated and optimized for foaming at Sabic’s Foam Innovation Center (FIC) in the Netherlands, which is equipped with most foam technology capabilities as well as analytical equipment.

About the Author(s)

You May Also Like