At least 27% of the new LNP Elcrin compound is composed of recycled PET water bottles, according to Sabic.

May 3, 2023

Upcycled polybutylene terephthalate (PBT) resin with thin-wall, non-brominated/non-chlorinated flame retardance (FR) has been added to Sabic’s portfolio of iQ compounds. LNP Elcrin WF0051iQ is suited for the fabrication of miniaturized electrical components as well as critical medical devices and appliance applications, according to Sabic.

The petrochemicals giant based in Riyadh, Saudi Arabia, said that the new grade will increase its already significant diversion of post-consumer polyethylene terephthalate (PET) water bottles, which are chemically upcycled into PBT resin. At the end of 2022, the company said it had already diverted 400 million half-liter bottles through its iQ upcycling technology.

Reduced carbon footprint

LNP Elcrin WF0051iQ has an 11% smaller carbon footprint than standard, fossil-based virgin PBT resin, according to Sabic, because each kilogram of material includes 39 recycled half-liter PET water bottles, representing at least 27% of the content. Moreover, SCS Global Services has audited and provided independent verification that the manufacturing processes for LNP Elcrin iQ compounded resins adhere to the SCS Recycled Content Standard, and that the supply chain meets criteria for responsible sourcing.

The ability to design thin walls also adds to the compound’s sustainability benefits, and the FR formulation helps avoid the use of bromine and chlorine, two semi-volatile organic compounds that are linked to health and environmental risks, said Sabic.

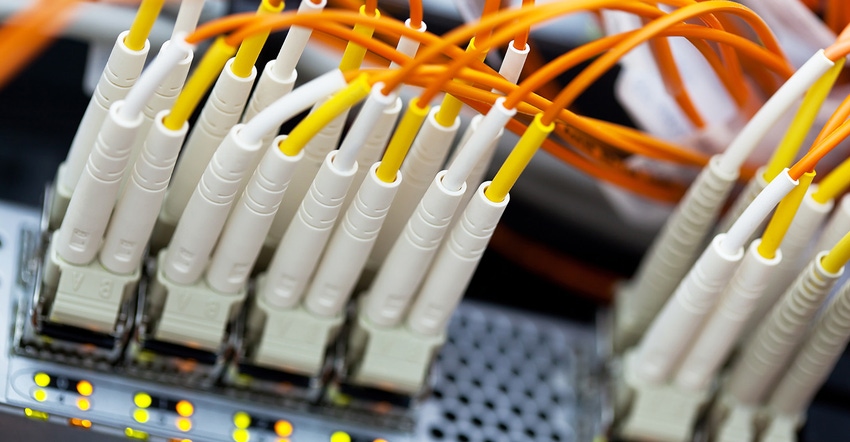

The combination of thin-wall FR, long-term property retention, and glass-fiber reinforcement for stiffness along with high flow to enable complex geometries makes LNP Elcrin WF0051iQ well suited for miniaturized electrical components such as connectors, switches, and sockets.

Resin meets UL94 V0 standard for fire resistance

The new resin is the first LNP Elcrin iQ compound to meet the UL94 V0 standard for fire resistance at 0.4 mm and has received a Yellow Card listing under the UL Plastics Recognition Program for the signature sustainability green color. The material’s relative thermal index (RTI) is 130°C at 0.4 mm, and the comparative tracking index (CTI) is 2, contributing to safety and reduced material requirements that can lower the cost of tooling and accelerate time to market, according to Sabic. In terms of processing, the material’s high flow and low abrasion properties support fast throughput compared with alternatives.

About the Author(s)

You May Also Like