Teknor Apex Group (Pawtucket, RI) expanded its Medalist line of medical-grade materials with a new elastomer-based non-polyvinyl chloride (PVC) offering for wire and cable applications. Nick Sandland, senior market manager-medical products for Teknor Apex's thermoplastics elastomer (TPE) division told PlasticsToday that Medalist 458 is based on its Elexar styrenic TPE material, specifically Elexar EL8431.

February 14, 2011

Teknor Apex Group (Pawtucket, RI) expanded its Medalist line of medical-grade materials with a new elastomer-based non-polyvinyl chloride (PVC) offering for wire and cable applications. Nick Sandland, senior market manager-medical products for Teknor Apex's thermoplastics elastomer (TPE) division told PlasticsToday that Medalist 458 is based on its Elexar styrenic TPE material, specifically Elexar EL8431.

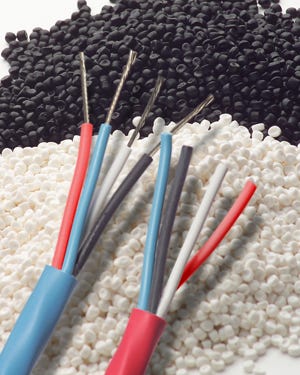

Teknor Apex's Medalist 458 styrenic elastomer aims to replace PVC in wire and cable applications. |

Teknor Apex's Medalist 458 styrenic elastomer aims to replace PVC in medical wire and cable applications. |

Sandland said the Medalist material's chemistry has the same formulation as its Elexar counterpart, but key raw materials have been replaced with FDA-compliant medical grades that are in line with cytotoxicity testing. The wire-and-cable material, which was launched last week in Anaheim at MD&M West (Feb. 8-10; Anaheim Convention Center) meets UL certification, and is RoHS and REACh compliant. Medalist 458 is manufactured in Teknor Apex's dedicated medical compounding facility in St. Albans, VT, which is now ISO 10993-5 compliant meeting the requisite risk management, sterile manufacturing, and traceability standards.

Sandland said the grades will target wire-and-cable applications within patient-monitoring devices, particularly those that are in contact with the skin and must be wiped clean. Teknor Apex did a series of chemical resistance evaluations on the materials to determine if they could withstand the range of disinfectants medical professionals currently use to help prevent hospital acquired infections (HAI). "We're very confident that Medalist 458 will meet the needs of the market," Sandland said, acknowledging that given the disparate chemistries between TPE and PVC there were some differences in how the two materials stand up to various chemicals.

Medalist 458 styrenic TPE has a Shore A hardness of 70, a flammability classification of HB (UL-94), and a maximum continuous-operating-temperature rating of 105ºC (UL-1581). It has passed standard tests for oil resistance after seven days at 60ºC and UV resistance after 720 hours. These properties lend themselves to applications in hospital and healthcare environments requiring excellent flexibility, durability, and chemical resistance, according to Teknor Apex.

About the Author(s)

You May Also Like