A*STAR scientists in Singapore have invented a method that uses additive manufacturing techniques to create lightweight lattice structures with improved stiffness and strength. Medical implants and automotive and aerospace components are targeted.

March 12, 2018

Biomimetics—the field of inter-disciplinary research that mimics biological processes to engineer solutions for complex human problems—combined with advances in metal and polymer additive manufacturing, aka 3D printing, have led to a breakthrough in the production of more-robust lightweight materials and structures. Medical implants and automotive and aerospace components are among the applications that will benefit from the research conducted by A*STAR scientists in Singapore.

|

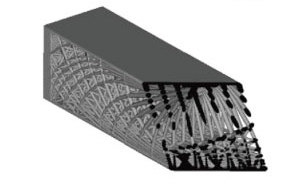

The lattice designs shown here, top to bottom, are uniform benchmark, |

Conventional manufacturing processes such as casting and machining are not well suited to the construction of strong lightweight structures, according to global research organization A*STAR. They also limit design possibilities. A*STAR scientists have invented a method that uses additive manufacturing techniques to create lightweight lattice structures with improved stiffness and strength, paving the way for new impact-absorbent materials and sandwich structures, according to the researchers.

“Lattice structures exceed the structural performance of conventional solid materials for use in lightweight sandwich cores, medical implants and a new class of lattice-type meta-materials with specific mechanical and thermal properties,” explained Stephen Daynes from A*STAR’s Singapore Institute of Manufacturing Technology, which worked on the project in collaboration with researchers from the National University of Singapore. “Using a new biomimetic method, we were able to create cellular and lattice structures similar to those seen in bamboo and human bones,” added Daynes.

The researchers determined the principal lines of stress, called isostatic lines, in the lattice using a method that combines topology and size optimization. This approach allows the size, shape and orientation of each cell in the structure to be tailored, significantly reducing the stress between neighboring lattice cells, noted a press release distributed by A*STAR. The design increased stiffness by 172% and strength by 100%, according to the researchers.

“Our technique can create lightweight, functionally graded lattices that greatly improve the stiffness and strength of additively manufactured sandwich structures without increasing their mass,” said Daynes. “These structures are particularly well suited to additive manufacturing processes since they are largely unconstrained by manufacturing complexity.”

“We plan to apply the methodology to three dimensional stress fields, where employing spatially graded lattices can lead to novel and more weight efficient materials,” said Daynes.

Related research was published in volume 127 of Materials & Design (Elsevier).

About the Author(s)

You May Also Like