Shape-shifting 4D hydrogels may lead to the development of human tissues, and even organs, that more closely resemble their natural counterparts, according to researchers.

March 5, 2021

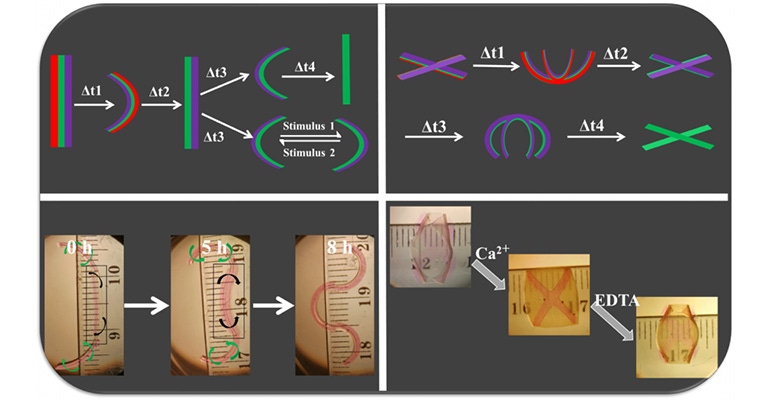

New 4D hydrogels — 3D materials that have the ability to change shape over time in response to stimuli — may lead to the development of human tissues, and even organs, that are more like their natural counterparts. The hydrogels can morph multiple times in a pre-programmed or on-demand manner in response to external triggers, according to researchers at the University of Illinois Chicago (UIC).

In a new Advanced Science study, the UIC researchers, led by Eben Alsberg, show that these new materials may be used to help develop tissues that more closely resemble their natural counterparts, which are subject to forces that drive movement during their formation.

“The hydrogels can be programmed or induced to undergo multiple controllable shape changes over time. This strategy creates experimental conditions to partially mimic or stimulate the continuous different shape changes that developing or healing tissues undergo,” Alsberg told Sharon Parmet in an article published on the UIC website. “It may let us study morphogenesis and also help us engineer tissue architectures that more closely resemble native tissues,” added Alsberg, who is the Richard and Loan Hill Professor of Biomedical Engineering and corresponding author on the paper.

The novel material is composed of different hydrogels that swell or shrink at different rates and degrees in response to water or the concentration of calcium. By creating complex layering patterns, the researchers can guide the conglomerate material to bend one way or another as the layers swell or shrink, writes Parmet.

“We can change the shape of these materials by adjusting, for example, the amount of calcium present,” said Alsberg, who also is professor of orthopaedics, pharmacology, and mechanical and industrial engineering at UIC.

The researchers were able to cause the hydrogel to form into pockets similar in shape to alveoli, the tiny sac-like structures in the lung where gas exchange takes place.

Not only are the hydrogels able to change their architecture multiple times, but they also are highly cyto-compatible, which means that cells can be incorporated in the material and will remain alive. This is not possible with many existing 4D materials, according to the researchers.

The research was supported by grants from the National Institutes of Health’s National Institute of Arthritis and Musculoskeletal and Skin Diseases, the National Institute of Biomedical Imaging and Bioengineering, and the National Heart, Lung and Blood Institute.

This article is courtesy of MD+DI's sister publication Plastics Today.

About the Author(s)

You May Also Like