MD&M West, the nation's largest medical manufacturing event, celebrates its 30th anniversary when it returns to Anaheim, CA, next week. The trade show and conference always features an array of leading-edge technologies that are often the foundation of tomorrow's breakthrough medical devices, and the 2015 event will build on that legacy. In the past couple of weeks, PlasticsToday has reported on some of the conferences and presentations that are part of this event; links to these articles are included at the end.

February 2, 2015

has reported on some of the conferences and presentations that are part of this event; links to these articles are included at the end. This time, we would like to draw your attention to four exhibitors that merit your attention.

LSR molding

Described as a step change in liquid silicone rubber (LSR) processing, Silcotech (Bolton, ON, Canada) has developed a multi-shot processing system capable of simultaneously molding nine discrete substrates or shapes in a range of durometers, textures and colors using QP1 silicone elastomers from Dow Corning (Midland, MI). Both companies will feature this technology and its current and potential applications at their respective booths at MD&M West.

Silcotech's multi-shot silicone system leverages the full range of durometers offered across Dow Corning's QP1 product family within a single application, while maintaining processing costs comparable to a single-shot system thanks to the material's fast cure and easy processing.

"In today's fiercely competitive marketplace, medical device manufacturers need to innovate designs with increasingly varied yet closely integrated functionality, while maintaining tight control over production costs," said Roger Hendrick, Application Engineer, Dow Corning Healthcare, in a prepared statement. "Our portfolio of QP1 LSRs gave Silcotech a solid materials foundation on which to build its new processing technology to meet this competitive demand. Our close collaboration has delivered results for high-output molding of intricate medical device designs."

To showcase the technology, Silcotech will produce multi-durometer phone covers at booth 1259 that seamlessly integrate eight discrete QP1 silicone elastomer grades in one of nine different colors. Dow Corning will feature finished samples of the covers accompanied by an in-depth technical video of the innovative molding process at booth 2027.

Sealing technologies

Trelleborg Sealing Solutions (Fort Wayne, IN) reports that it will highlight its "shoulder-to-shoulder" approach to engineering design, advanced delivery and LSR technology at booth 1554, where it will display a number of sealing technologies it has developed for medical device OEMs. Recent achievements in seal, bearing, and tubing designs and LSR molded components that have contributed to advances in insulin inhalers, drug-delivery devices and surgical instruments are among the featured products.

"Newly developed insulin inhalers and intelligent surgical powered tools now require uncompromising quality and longevity of sealing solutions," says Luis Tissone, Life Sciences Director for Trelleborg Sealing Solutions in the Americas. "These demands as well as the evolution and speed in which medical devices are evolving, has further validated our investment in R&D centers, cleanrooms and state of the art manufacturing facilities to ensure we are moving as quickly technologically as our customers."

Bioresorbable materials

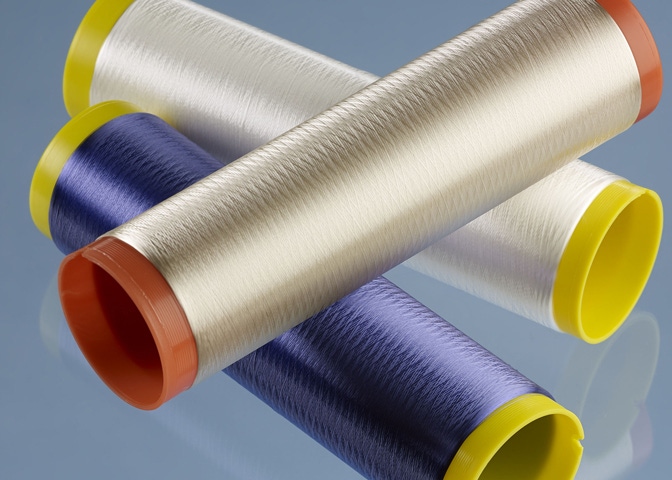

|

Image courtesy Teleflex Medical OEM. |

Betting on the bioresorbables market, Teleflex Medical OEM (Wayne, PA) has announced a significant expansion of its manufacturing infrastructure and production capabilities for sutures, fibers and resins that resorb in the body over time. The multimillion-dollar investment at the Mansfield, MA, facility includes expanded production and cleanroom areas, a new customer support center and additional areas for research and development activities.

Teleflex Medical developed the Bondek Plus (polyglycolic acid) coated suture, which holds together body tissues for a determined period of time to aid in healing and then safely resorbs into the body.

In addition to suture, the Mansfield facility will house manufacturing operations for specialized yarns of polyglycolic acid (PGA), poly-L-lactide (PLLA) and polyglycolic acid-co-poly-L-lactic acid (PGLA). These bioresorbable yarns can be knitted, woven, felted or braided into bioresorbable components used in textile-based medical devices.

Taking a different tack on bioresorbables, Secant Medical (Perkasie, PA) will showcase its Regenerez technology, based on poly glycerol sebacate (PGS) at booth 1973.

Coating a partially or fully resorbable structure with PGS can improve coating biocompatibility by promoting tissue in-growth, enabling controlled drug release and solving compliance mismatch issues with bodily tissue that may occur with other bioresorbable materials, says Secant.

Some key features of a PGS coating include conformal properties for fine architectures such as fibrous woven, braided and knitted structures as well as perforated structures. The tunable degradation profile is another desirable property. To learn more about Regenerez, read "Bioresorbable technology from Secant Medical addresses limitations of PLA and PGA."

MD&M West, co-located with PLASTEC West, comes to the Anaheim Convention Center in Anaheim, CA, from Feb. 10 to 12.

Previously published previews of MD&M West 2015 conferences and presentations:

Former NBA player turned medical device inventor to speak at MD&M West

The challenges of medtech 3D printing

Bioprinting comes alive (but not in the way you might imagine it)

An FDA perspective on the use of 3D printing in medical applications

About the Author(s)

You May Also Like