Engel will highlight the liquid-silicone-rubber micro-molding system during its virtual e-xperience event in October.

September 9, 2020

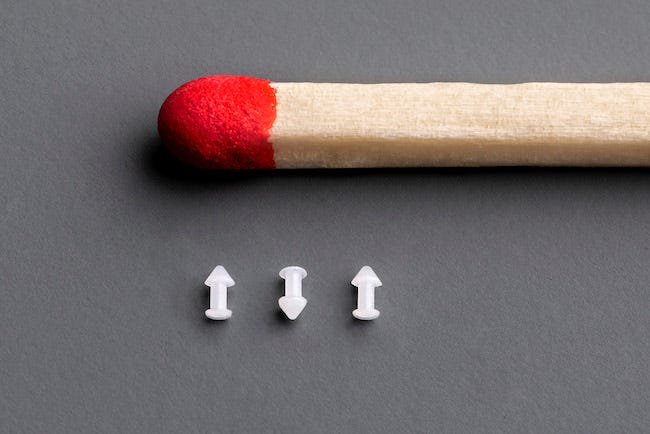

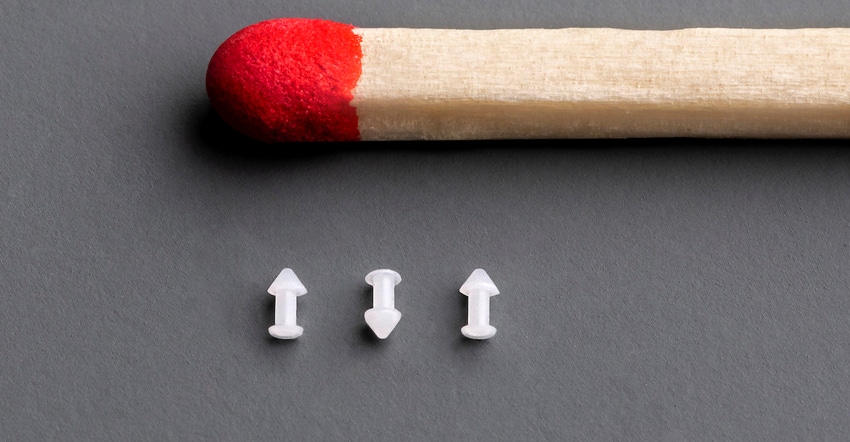

One of the highlights of Engel’s virtual e-xperience event next month is the unveiling of a new liquid-silicone rubber (LSR) micro-molding system that produces precision medical components in shot weights well under 0.1 grams. Developed by injection molding machine maker Engel in collaboration with LSR tooling specialist ACH Solution, the technology enables the precise, repeatable, and cost-effective production of an ophthalmological component weighing a scant 0.0013 grams.

Scheduled from Oct. 13 to 16, 2020, Engel’s e-xperience is designed to provide the company with an online platform to feature innovations it was planning to exhibit at Fakuma, which has been cancelled this year because of COVID-19 concerns.

Flexibility a top priority

This application uses a 32-cavity valve-gate cold runner mold running on an Engel e motion 50/30 TL machine to produce connecting parts used in ophthalmic diagnostic instruments. The parts measure 1.7 mm long and 0.9 mm diameter. The all-electric and tie-bar-less Engel injection molding machine is equipped with an LSR metering pump from ACH Solution, an Engel viper 6 linear robot for micropart removal and placement on a conveyor belt, and a camera system for quality control, also developed by ACH Solution.

|

The liquid-silicone-rubber components measure 1.7 mm in length, 0.9 mm in diameter, and weigh just 0.0013 grams. Image courtesy Engel. |

Flexibility was a top priority during development of the micro-molding system, stressed Engel. A quick-coupling mechanism enables swapping out the micro-molding unit for a conventional screw injection unit in less than 30 minutes, maximizing throughput of the injection molding machine.

Another unique feature of the Engel machine is the large platen enabled by the tie-bar-less design. Since there are no tie bars in the way, the platens can be fully utilized right up to the edge: Large multi-cavity molds can fit on comparatively small injection molding machines, reducing the system’s footprint and increasing productivity per unit of area. This, in turn, ensures relatively low unit costs, according to Engel.

The medical device and consumer electronics sectors are the target markets for the e-motion TL machine in combination with the new micro-injection unit. Engel believes that automotive OEMs also may gravitate toward this technology, as electric and self-driving cars will require large numbers of micro-molded LSR parts. Engel said that it also will use the new micro-injection unit in multi-component processes, injecting sealing elements with very small shot volumes directly onto a base body, for example.

About the Author(s)

You May Also Like